Hangzhou Guheng Energy Technology Co., Ltd.

New energy service technology solution expert

Menu

With the rapid development of the electric vehicle industry, power batteries as energy storage are becoming increasingly popular. Power batteries are an important part of electric vehicles, and their performance and health directly affect the mileage and service life of electric vehicles. With the increasing number of electric vehicles, the after-sales problems of power battery packs are becoming more and more serious. Proper maintenance of power battery packs can extend their service life and improve battery performance. Hangzhou Guheng Energy Technology Co., Ltd. has launched a series of special maintenance equipment for power battery pack after-sales outlets, which can perform one-stop inspection and maintenance of battery cells, battery modules and battery packs.

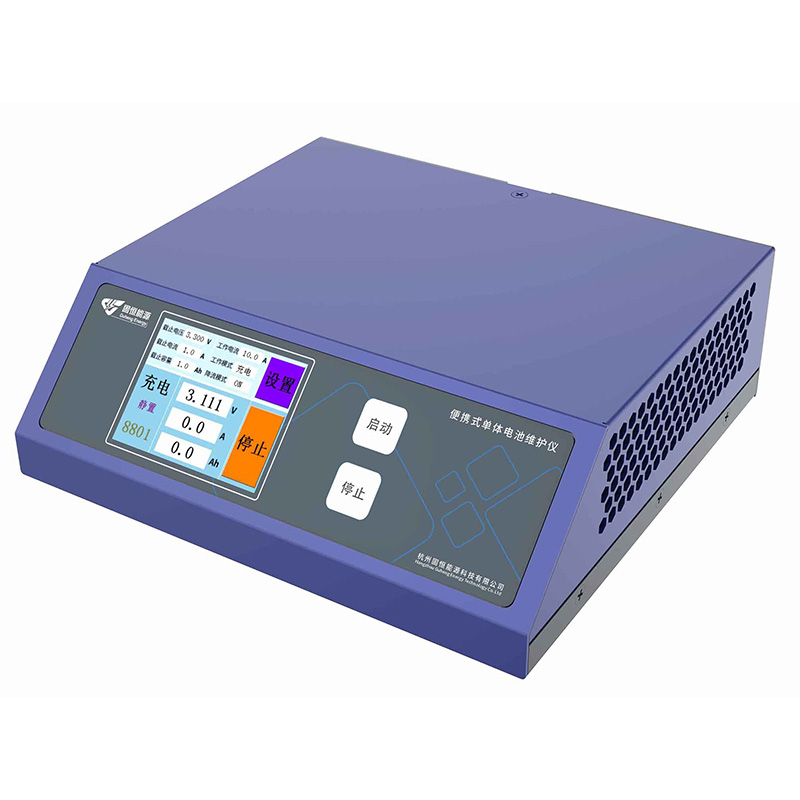

The portable single-cell battery maintenance instrument PBM-S series can realize functions such as single-cell capacity verification, SOC adjustment and voltage difference adjustment between battery strings through fast and accurate charging and discharging maintenance of single-cell batteries.

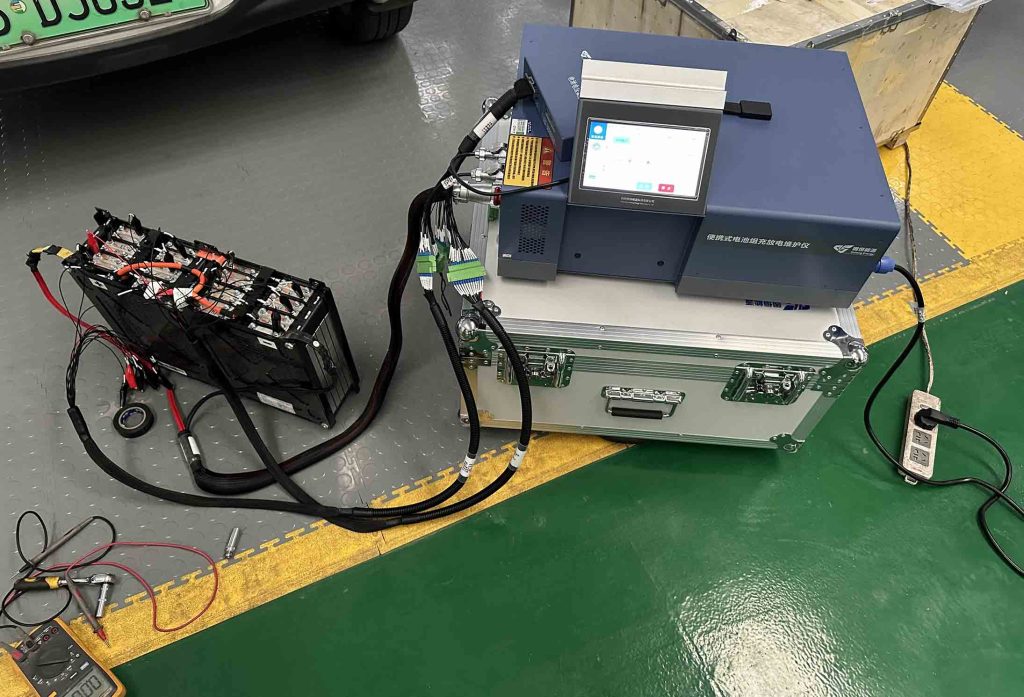

The portable battery pack charging and discharging instrument PBM-M series has the functions of battery module charging/discharging, battery module capacity verification, SOC adjustment and voltage adjustment between modules. It can be connected to an external acquisition box to obtain single cell voltage and temperature, and supports BMS communication to obtain single cell information. The equipment has the characteristics of extremely wide output voltage adaptability range, full protection, high reliability and small size.

The portable battery pack balance maintenance instrument PBM-P series regulates the voltage and SOC of each single battery by controlling the charge and discharge of the cells in the battery module, thereby solving the problem of reduced battery pack capacity and shortened cycle life due to voltage differences between single batteries in the battery module.

The ETS-AE series of battery pack service terminal final inspection instruments are designed for new energy vehicle battery packs to perform fault diagnosis, maintenance, and detection of whether their functional performance meets the commissioning requirements at service terminals (service stations). At the same time, they comply with terminal service processes, generate data and related test reports, and support uploading to the cloud. They are low-cost, highly integrated intelligent equipment developed to adapt to service terminal scenarios, thereby reducing the operating costs of service terminals and reducing dependence on the skills and sense of responsibility of operating technicians, while ensuring the consistency and integrity of maintenance service quality. It includes multifunctional detection of battery pack insulation resistance, high-voltage relays, BMS functions, interlocking, thermal management, fast and slow charging signals, high-voltage port voltage, etc.

The QMM series of portable air tightness leak testers are special test equipment developed for the new energy field, suitable for air tightness testing of liquid cooling panels, PDUs, PEUs, EDSs, battery packs, etc. The equipment uses our company's unique air pressure control technology to effectively solve the problems of automatic adjustment of test air pressure, air pressure stability, and high-precision sampling.

The BST-DW series of battery pack service terminal maintenance testers are used for new energy vehicle battery packs in service terminals (service stations) to perform capacity verification, SOC adjustment, fault diagnosis, and maintenance, and at the same time, comply with terminal service processes to generate data and related test reports. The maintenance tester is a low-cost, highly integrated intelligent device developed for service terminal scenarios that can be expanded and uploaded to the cloud, thereby reducing the operating costs of the service terminal and reducing the reliance on the skills and sense of responsibility of the operating technicians, while ensuring the consistency and integrity of the maintenance service quality.