With the rapid development of the new energy industry, batteries, as the core components of energy storage and conversion, directly determine the efficiency and reliability of electric vehicles, energy storage systems, and renewable energy equipment. Battery pack charge-discharge testing equipment, as a critical tool for evaluating battery performance, is increasingly becoming an indispensable technical pillar in the new energy field. This article will delve into the core functions of battery pack charge-discharge testing equipment, its application scenarios in the new energy sector, future development trends, and the technical advantages and solutions offered by Guheng Energy in this domain.

Core Functions and Technical Features of Battery Pck Charge-Discharge Testing Equipment

Battery pack charge-discharge testing equipment simulates the charging and discharging processes of batteries in real-world use, detecting their performance parameters to provide data support for research, production, and maintenance. Its core functions and technical features include the following aspects:

High-Precision Current and Voltage Measurement

High-precision current and voltage measurement is the foundational function of battery pack charge-discharge testing equipment. By accurately measuring voltage and current changes under different operating conditions, it can assess battery capacity, internal resistance, and cycle life. For instance, Guheng Energy’s equipment achieves microampere-level current control, ensuring the reliability of test results, which is particularly crucial for high-performance batteries like lithium-ion batteries.

Multi-Channel Parallel Testing Capability

Modern battery testing equipment typically features multi-channel parallel testing capabilities, allowing simultaneous testing of multiple batteries or battery packs. This not only improves testing efficiency but also reduces time costs for businesses.

Data Acquisition and Analysis Functions

Battery testing is not just about recording data; it also requires in-depth analysis. Advanced testing equipment comes with built-in data acquisition systems that monitor parameters such as temperature, voltage, and current in real time and generate visualized reports. This functionality provides a scientific basis for optimizing battery performance.

Safety Protection Mechanisms and Their Importance

During the charge-discharge process, batteries may face risks such as overcharging, over-discharging, or short-circuiting, making safety protection mechanisms essential. Equipment is typically equipped with overvoltage protection, overcurrent protection, and temperature monitoring systems to ensure a safe and controlled testing process. This protects not only the equipment itself but also the safety of operators.

Key Application Scenarios of Battery Pack Charge-Discharge Testing Equipment in the New Energy Sector

The rapid growth of the new energy sector has provided vast opportunities for battery pack charge-discharge testing equipment. Below are its specific applications in several key scenarios:

Applications in the Electric Vehicle Industry

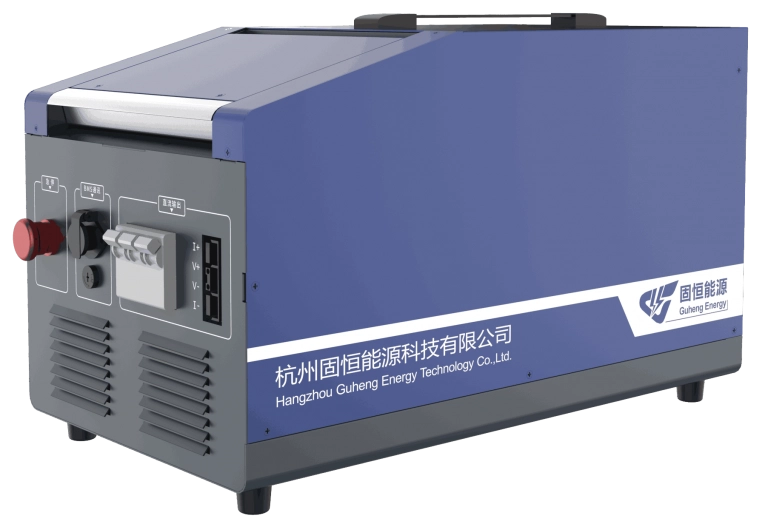

The performance of electric vehicle batteries directly impacts range and safety. Battery pack charge-discharge testing equipment is used to evaluate the cycle life, charge-discharge efficiency, and performance of power batteries under high- and low-temperature conditions. For example, Guheng Energy’s Portable Battery Pack Charge/Discharge Maintenance Equipment-PBM-MW-E-12060 provides precise testing support for EV batteries.

Testing Needs in Energy Storage Systems

Energy storage systems play a vital role in grid peak shaving and renewable energy integration. battery pack charge-discharge testing equipment assesses capacity degradation and stability in storage batteries, ensuring the long-term reliability of the system. Multi-channel testing capability is particularly valuable here, enabling one-time testing of large-scale battery packs.

Performance Evaluation of Renewable Energy Generation Equipment

Solar and wind power generation equipment relies on batteries to store excess energy. Testing equipment simulates various charge-discharge cycles to evaluate battery suitability in renewable energy systems, optimizing system design and operational efficiency.

Future Development Trends of Battery Pack Charge-Discharge Testing Equipment

As technology advances, battery pack charge-discharge testing equipment continues to evolve, with future trends primarily reflected in the following directions:

Integration of Intelligent and Automated Technologies

The introduction of artificial intelligence and automation will make testing equipment smarter. For example, machine learning algorithms can predict battery lifespan, or testing parameters can be automatically adjusted to suit different battery types. This trend will significantly enhance testing efficiency and accuracy.

Miniaturization and Portability Direction

The demand for portable equipment is growing, especially in on-site maintenance scenarios. Guheng Energy’s Portable Battery Pack Charge/Discharge Maintenance Equipment-PBM-MW-A-28020 exemplifies this trend, balancing portability with high performance.

Introduction of Eco-Friendly and Energy-Saving Design Concepts

The essence of the new energy industry is green and low-carbon, and testing equipment must align with this philosophy. Future equipment will adopt low-power designs and minimize energy waste during testing to achieve environmental goals.

Below is a brief comparison of future trends:

| Trend Direction | Current Features | Future Outlook |

| Intelligent & Automated | Manual Parameter Adjustment | AI-Optimized Testing Processes |

| Miniaturization & Portability | Fixed Large-Scale Equipment | Widespread Use of Lightweight Portable Devices |

| Eco-Friendly & Energy-Saving | High Energy Consumption | Low-Power, Sustainable Design |

Guheng Energy: A Reliable Expert in New Energy Service Technology Solutions

As a technical pioneer in the new energy field, Guheng Energy leverages over a decade of industry experience and technological innovation to provide customers with exceptional battery testing solutions.

Core Technical Advantages of Guheng Energy

Guheng Energy holds over 30 patents (including 6 invention patents) and 28 software copyrights, developing several industry-first products such as the Battery Pack Service Terminal Final Inspection Instrument (EOS-TEST) and Battery Pack Balancing Maintenance Equipment. These innovations ensure the high precision and reliability of its testing equipment.

Providing Comprehensive Battery Testing Solutions

From portable maintenance instruments to large-scale testing systems, Guheng Energy’s products cover the entire lifecycle of battery research, production, and after-sales maintenance. For instance, its portable battery pack charge discharge maintenance equipment PBM-M series is suitable for various scenarios, meeting diverse customer needs.

Successful Practices and Case Studies in the New Energy Sector

Guheng Energy actively participates in industry technical seminars and standard-setting, with its products certified under ISO9001 and multiple CE certifications. Many well-known new energy companies have adopted its testing equipment, with successful cases including EV battery testing and energy storage system optimization projects.

Frequently Asked Questions

Why Is Choosing High-Precision Testing Equipment Crucial for the New Energy Industry?

High-precision testing equipment can capture subtle changes in battery performance, such as capacity degradation rates and internal resistance increases, which are critical for battery R&D and quality control. For electric vehicles, for example, substandard battery performance could lead to insufficient range or safety hazards. High-precision equipment provides reliable data to help companies optimize battery design, extend lifespan, and enhance product competitiveness.

What Are Guheng Energy’s Advantages in After-Sales Service?

Guheng Energy offers a fast-response after-sales service system, including equipment installation guidance, remote technical support, and regular maintenance. Additionally, its products are insured, providing customers with extra assurance. Whether it’s equipment malfunctions or usage queries, customers can promptly receive professional solutions.

How to Evaluate Whether a Battery Pack Charge-Discharge Testing Equipment Meets Your Needs?

When evaluating equipment, consider the following points:

- Testing Precision: Does it meet the measurement requirements for battery parameters?

- Scope of Application: Does it support the target battery types (e.g., lithium-ion, lead-acid)?

- Functionality: Does it offer multi-channel testing, data analysis, etc.?

- Portability and Cost: Does it align with the usage scenario and budget?

It’s recommended to test the equipment based on actual needs or consult Guheng Energy’s professional team for tailored advice.

Conclusion

Battery pack charge-discharge testing equipment is a cornerstone of the new energy industry’s development, with its high precision, multifunctionality, and safety providing robust technical support for electric vehicles, energy storage systems, and renewable energy equipment. Guheng Energy, with its advanced technology and comprehensive solutions, has become a reliable partner in this field. Looking ahead, as trends toward intelligence and portability deepen, such equipment will play an even greater role in the new energy sector. If you have battery testing needs, feel free to visit the Guheng Energy homepage to learn more about product details and technical support.