Driven by modern technology, portable battery charge and discharge maintenance instruments are rapidly developing towards intelligence. Single-function instruments, isolated data, and a heavy reliance on manual experience have become bottlenecks hindering efficiency and profitability. With the continuous advancement of new energy technologies, portable battery charge and discharge maintenance instruments are playing an increasingly important role in various fields. As a technology provider deeply rooted in the industry, Guheng Energy believes that the evolutionary path of portable maintenance instruments is clear: in-depth development towards intelligence, integration, and cloud computing, completely reshaping workflows.

Intelligence: From “Tool” to “Smart Diagnostic Expert”

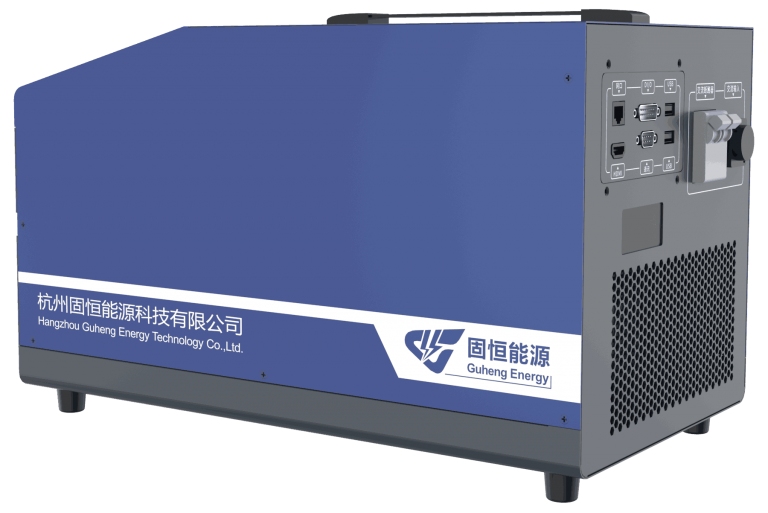

The core of intelligence is to enable devices to “think.” Its value goes far beyond measurement itself; it lies in understanding data and making decisions. With the widespread adoption of artificial intelligence, portable battery charge and discharge maintenance instruments are beginning to integrate AI algorithms to enhance data analysis capabilities. This technological upgrade not only enables more accurate monitoring of battery status but also predicts potential problems, thereby increasing device reliability and service life. Guheng Energy’s PBM-MW-E-12060 portable battery pack charge and discharge maintenance instrument exemplifies this trend. It features a built-in diagnostic algorithm trained on massive amounts of data, enabling it to perform logical reasoning like a seasoned technician.

Integration: From “Standalone Tool” to “All-in-One Mobile Workstation”

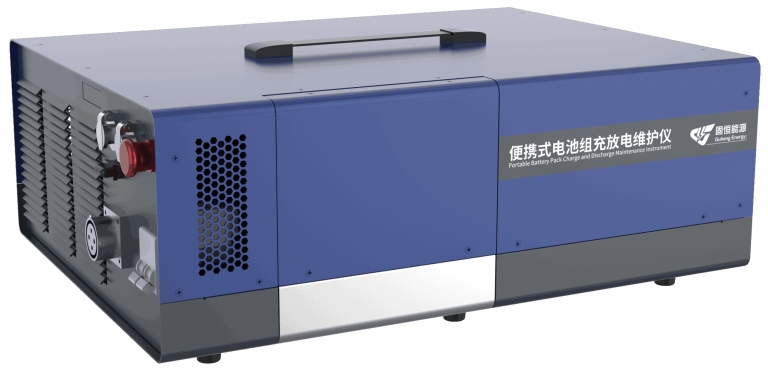

Integration aims to simplify complexity. By integrating functions, it consolidates the responsibilities of multiple devices into a single unit, creating a highly portable, all-in-one workstation. Guheng Energy’s portable battery pack charge and discharge maintenance instrument, such as the PBM-MW-A-28020, offers high flexibility and expandability through a modular design. It integrates multiple functions, including battery charging and discharging, temperature monitoring, and data logging, into a single unit. Users can complete multiple tests with a single connection, eliminating the hassle and risk of repeated cable disconnection and error. This “one-machine, multi-functional” design significantly reduces equipment procurement costs and simplifies operational processes, making it particularly suitable for complex scenarios such as field inspections and comprehensive performance evaluations.

Cloud-based: From “Local Storage” to “Smart Cloud Ecosystem”

Cloud-based integration is key to breaking down data silos. It enables data mobility, enabling collaborative operations, deep mining, and asset management. No matter how intelligent a device is, its value cannot be maximized if the data is stored only locally. Guheng Energy’s cloud platform provides a data home for all smart devices. These devices feature an easy-to-use interface and real-time data feedback, allowing users to easily understand device operating status and improve work efficiency. After our equipment inspections are completed, data is automatically synchronized to the cloud via the network, automatically generating and storing a unified battery health report. This means: managers can globally view the battery health status of all vehicles from their office, enabling precise resource scheduling; technicians can access historical data for comparison and accurately track battery performance degradation trends; and decision-makers can analyze this vast database to gain insights into failure patterns and optimize procurement and maintenance strategies. Cloud-based integration builds a complete digital ecosystem, making the full lifecycle management of battery assets transparent and efficient.

A Practitioner Turning the Future into Reality

We firmly believe that future competition will be a competition of ecosystems. Guheng Energy is committed to working with all industry partners to promote the paradigm shift in battery maintenance from “passive repair” to “active health management” through intelligent tools and platforms, ushering in a new era of intelligent maintenance. We are committed to providing customers with not just a single tool, but a complete solution that improves efficiency, ensures safety, and unlocks the value of data. We sincerely invite you to join us in embracing the new era of intelligent battery maintenance and seize the development opportunities.

FAQ

Q: How accurate is intelligent diagnosis? Can it truly replace the experience of experienced technicians?

A: Guheng’s intelligent diagnosis is based on a vast library of real-world fault cases and algorithmic models. Our goal is not to replace experts, but to digitize and standardize their experience, enabling every technician to possess “expert-level” preliminary diagnostic capabilities. This will significantly improve efficiency and diagnostic consistency, and assist experienced technicians in making complex decisions.

Q: Is the cloud data in the portable maintenance instrument secure?

A: Security is the primary consideration for cloud-based deployment. Guheng Energy uses bank-grade encryption for transmission and storage, and has a strict permissions management system to ensure that all data is visible only to the customer, fully safeguarding their data privacy and security.

Q: Will the operation of the intelligent maintenance device be more complicated?

A: Quite the contrary. The core purpose of intelligence is to simplify the complex. Through AI and automation, Guheng’s intelligent maintenance device is designed to offload complex analysis and judgment to the device. Users only need to perform simple operations (such as one-click testing) to obtain professional diagnostic results, significantly reducing the operational barriers.

Q: Can existing maintenance devices be upgraded with these new features in the future?

A: Guheng Energy’s products are designed from the outset to allow for continuous upgrades of some functions. Software and some intelligent algorithms can be upgraded online via OTA (Over-the-Air) updates. However, for integrated functions that require new hardware, upgrading to a new model may be necessary.