Pain Points and Integrated Solutions in New Energy Vehicle Maintenance

In today’s rapidly developing new energy industry, battery packs, as core components of electric vehicles and energy storage systems, face numerous challenges in maintenance and testing. Traditional maintenance sites often involve numerous tools and complex operations, leading to frequent equipment switching by technicians, which is time-consuming, labor-intensive, and prone to errors. This not only reduces efficiency but may also affect diagnostic accuracy.

As a professional manufacturer of new energy service technology solutions and battery maintenance and testing instruments, Guheng Energy understands these pain points. Therefore, we have launched a series of integrated devices, among which the BTS series Battery Pack Service Terminal Maintenance and Testing Instrument stands out with its multi-functional integrated design, becoming the “all-round diagnostic expert” in the new energy vehicle maintenance field.

Guheng Energy Battery Pack Service Terminal Maintenance and Testing Instrument

Definition and Core Function

The Battery Pack Service Terminal Maintenance and Testing Instrument is a multi-functional integrated device specifically designed for new energy battery packs. It is mainly used for the daily maintenance, fault diagnosis, and performance optimization of battery packs, and can monitor the battery health status in real time to ensure the safe and stable operation of the system. As an “all-around diagnostic expert,” its core function lies in integrating multiple testing functions into one, avoiding the limitations of traditional distributed tools. By connecting to the battery pack port, this device can quickly collect data, analyze problems, and provide optimization suggestions, making it suitable for electric vehicle repair, energy storage station maintenance, and other fields. At Guheng Energy, these products emphasize practicality and reliability, helping users shift from reactive maintenance to proactive prevention.

Product Features

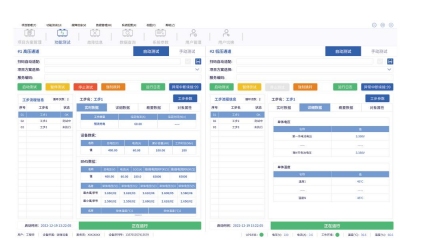

At Guheng Energy, we are committed to providing high-quality new energy maintenance solutions and have developed several industry-leading products. For example, the Battery Pack Service Terminal Maintenance Tester (BTS) supports the input of various battery pack serial number (SN) information, using wireless technology to quickly scan battery data for efficient identification and diagnosis. It supports high-current, high-power operation, meeting the comprehensive maintenance needs of modules and battery packs. These products all employ advanced algorithms and high-precision sensors to ensure data accuracy and are equipped with a user-friendly interface for easy operation.

Multifunctional Integration Advantages

Voltage Detection Function

Voltage detection is a fundamental function of battery pack maintenance. Our Guheng Energy Battery Pack Service Terminal Maintenance and Testing Instrument (BTS) incorporates a high-precision voltage sensor, enabling real-time monitoring of individual cell and overall pack voltage, covering a range of 50-1000V, and supporting multi-channel parallel detection. This helps to detect overcharge or over-discharge problems early, avoiding safety hazards.

Internal Resistance Testing Function

Internal resistance testing is used to assess the degree of battery aging. This device integrates an internal resistance measurement module, quickly calculating the internal resistance value using the AC impedance method with an accuracy of 0.1mΩ. Combined with our portable battery pack equalization maintenance instrument, internal resistance can be tested simultaneously during equalization, achieving multiple uses in one device.

Insulation Verification Function

Insulation verification ensures battery pack safety. Our products employ high-voltage insulation testing technology, with a verification range of 500V-5kV, capable of detecting whether insulation resistance meets standards, preventing short-circuit risks.

SOC Calibration Function

SOC (State of Charge) calibration is key to optimizing battery performance. The equipment precisely calibrates SOC using coulomb counting and voltage curve matching algorithms, with an error of less than 1%. This, combined with the capacity testing function of the portable battery pack charge/discharge maintenance instrument PBM-BW-A-100080, provides a comprehensive calibration solution.

Other Auxiliary Functions

In addition to the core functions, our product also includes data logging, interruption resumption, and forced jump functions. The simple, intuitive, and feature-rich human-machine interface greatly facilitates user operation. Historical data can be viewed via an app, and cloud backup is supported for easy remote diagnostics.

Improving Maintenance Efficiency and Professionalism

Simplifying Operation Processes

Traditional maintenance requires switching between multiple devices, while our integrated design condenses the process into a single operation. Technicians only need to connect to the Battery Pack Service Terminal Maintenance and Testing Instrument (BTS) and select a mode to complete all tests, saving over 50% of time.

Improving Diagnostic Accuracy

Through integrated algorithms, the equipment automatically analyzes data, reducing human error. Combined with the intelligent balancing of the portable battery pack balancing maintenance instrument PBM-PW-B-4805, the diagnostic accuracy rate is increased to 95%.

Reduce Maintenance Costs

Integrated equipment reduces tool procurement and training costs. Using the portable battery pack charge/discharge maintenance instrument PBM-BW-A-100080 can extend battery life by 20%, indirectly reducing replacement costs.

Real-world Application Scenarios

Electric Vehicle Maintenance Case

In electric vehicle 4S shops, technicians use the Battery Pack Service Terminal Maintenance and Testing Instrument (BTS) to quickly diagnose battery faults. After identifying imbalances through voltage and internal resistance testing, they combine it with the portable battery pack balancing maintenance instrument PBM-PW-B-4805 for balancing, reducing repair time to 1 hour.

Energy Storage System Maintenance Case

In energy storage station maintenance, the portable battery pack charge/discharge maintenance instrument can be used for capacity testing and SOC calibration, ensuring stable system operation and avoiding peak-hour failures.

Industrial Battery Pack Testing Case

In industrial applications, this equipment tests the insulation and internal resistance of large battery packs, supporting batch processing and improving production efficiency.

FAQ

Q: What is the Battery Pack Service Terminal Maintenance and Testing Instrument?

A: The Battery Pack Service Terminal Maintenance and Testing Instrument is a multi-functional integrated device launched by Guheng Energy, used for the maintenance and testing of new energy battery packs. It integrates multiple testing functions to help technicians quickly diagnose battery health and improve maintenance efficiency.

Q: What are the main functions of Guheng Energy’s Battery Pack Service Terminal Maintenance Tester?

A: This device mainly integrates voltage detection, internal resistance testing, insulation verification, and SOC calibration functions. It supports a comprehensive battery pack inspection through a single terminal and also includes auxiliary tools such as data recording and report generation.

Q: How to use Guheng Energy’s Battery Pack Service Terminal Maintenance Tester?

A: To use it, first connect the device to the battery pack port, select the corresponding test mode, and follow the instructions to complete the test. Guheng Energy provides a detailed user manual and training to ensure technicians can quickly get started.

Q: Why choose Guheng Energy’s Battery Pack Service Terminal Maintenance Tester?

A: As an all-around diagnostic expert, it solves the pain points of traditional maintenance tools being numerous and complex to operate, providing an integrated solution that improves efficiency and reduces error rates, suitable for various new energy scenarios.

Q: Can the Battery Pack Service Terminal Maintenance Tester improve the efficiency of new energy maintenance?

A: Yes, through multi-functional integration, this device can condense multiple tests into a single operation, reduce tool changeover time, improve diagnostic speed and professionalism, and significantly optimize the maintenance process.