Key Challenges and Industry Needs in Battery Module Welding

In today’s rapidly developing new energy vehicles and energy storage systems, the production quality of battery modules (PACKs), as core energy units, directly determines the performance, safety, and lifespan of end products. Among these processes, the welding of the aluminum palladium (APA) and nickel sheets connecting the battery cells is akin to “heart bypass surgery” in battery module manufacturing. This step requires the weld to possess not only extremely high conductivity and mechanical strength but also to minimize thermal damage to the delicate battery cells.

However, traditional welding methods, such as resistance welding, result in high heat input, easily leading to damage to the internal structure of the battery cells and deformation of the outer casing. While conventional laser welding offers some improvement, it still has stringent requirements for workpiece assembly precision, and its welding efficiency remains insufficient when dealing with dense weld points, becoming a key bottleneck restricting production line cycle time and product consistency.

As a technology solutions expert deeply rooted in the new energy field, Guheng Energy understands this pain point. We are committed to providing the industry with solutions through innovative technologies and equipment. This article will delve into how to utilize advanced galvanometer laser welding technology, particularly our swing-arm galvanometer laser welding machine, to achieve efficient and precise welding of aluminum-palladium and nickel sheets, helping customers overcome production bottlenecks and reach new heights in intelligent manufacturing.

Analysis of the Core Challenges in Battery Module Welding

Challenges Arising from Material Properties: Aluminum-Palladium and Nickel Sheets

Battery module welding is by no means easy, with the primary challenge stemming from the materials themselves:

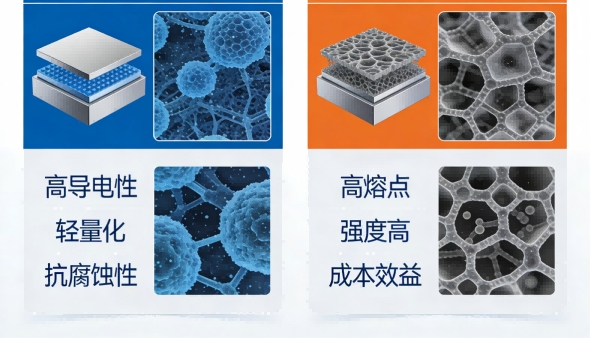

- Aluminum-Palladium (APA):Possesses high reflectivity (over 90% reflectivity to common near-infrared lasers), high thermal conductivity, and readily forms a dense, high-melting-point alumina film on its surface. These characteristics make it difficult to stably and efficiently absorb laser energy, easily leading to instability in the welding process and defects such as porosity and cracks.

- Nickel:Although its weldability is superior to aluminum, when welding dissimilar metals with aluminum-palladium, significant differences exist in melting point, coefficient of thermal expansion, and metallurgical compatibility. This easily leads to the formation of brittle intermetallic compounds at the weld interface, affecting the long-term reliability of the joint.

- Stringent Performance Requirements:Welded joints must ensure extremely low contact resistance to guarantee excellent conductivity, while possessing sufficient tensile and shear strength to withstand vibrations and shocks during vehicle operation or system operation.

Bottlenecks of Traditional Welding Processes

Traditional processes often fall short in addressing these challenges:

- Resistance Welding:Relies on high current passing through contact resistance to generate heat, resulting in a large heat-affected zone. This easily causes irreversible damage, such as shrinkage of the internal separator and electrolyte denaturation within the battery cell. Furthermore, controlling the surface quality and consistency of the weld joints is difficult.

- Traditional Laser Welding (Collimated Welding):The laser head or workpiece requires mechanical movement to complete the welding path. Although the heat input is relatively concentrated, the welding speed is limited by the mechanical movement speed. When welding hundreds or thousands of weld joints on battery modules, efficiency bottlenecks become apparent. Simultaneously, it is extremely sensitive to the assembly gaps between workpieces, placing extremely high demands on incoming material accuracy and tooling fixtures.

Galvanometer Laser Welding: An Innovative Solution for High-Efficiency and Precision Welding

Galvanometer Welding Technology Principles and Advantages

Galvanometer laser welding technology offers a revolutionary solution to the above problems. Its core lies in utilizing a high-speed galvanometer motor to drive a reflecting mirror, precisely and rapidly deflecting the laser beam, thereby achieving instantaneous jumping and scanning of the laser focus on the workpiece surface. This “beam-flying” method brings revolutionary advantages:

- Non-contact, high-speed scanning:The welding path is completed by beam scanning, with no inertial delay, and welding speeds can reach several meters or even tens of meters per minute, far exceeding mechanical motion methods.

- Extremely high processing precision and flexibility:Software can easily program any complex two-dimensional shape (such as circles, spirals, and polylines) to achieve various processes such as spot welding, sealing welding, and lap welding, making it particularly suitable for multi-point, multi-shape welding of busbars in battery modules.

- Precision thermal control:By precisely controlling the laser’s dwell time at each position (coordination of power, frequency, and speed), heat input can be controlled within an optimal range, achieving precision welding with a minimal heat-affected zone (HAZ).

How to Specifically Solve the Challenges of Aluminum-Palladium/Nickel Sheet Welding?

Guheng Energy’s galvanometer welding solution is based on a deep understanding of the properties of these materials:

- Overcoming the Challenges of High-Reflectivity Materials:Our system is equipped with a high-performance laser and intelligent waveform control. By optimizing the pulse shape (such as a pre-pulse spike), it can instantly break through the oxide layer on the aluminum surface, achieving stable energy coupling and ensuring stable arc initiation and aesthetically pleasing weld formation in aluminum-palladium welding.

- Achieving Reliable Joining of Dissimilar Materials:For nickel sheet welding and aluminum-nickel dissimilar welding, we precisely control the molten pool size and stirring through optimized parameters in our process database, suppressing excessive growth of brittle phases, thereby obtaining high-quality joints with good metallurgical bonding, low resistance, and high strength.

- Enhancing Production Line Adaptability and Yield:Galvanometer scanning welding has a higher tolerance for assembly gaps. Combined with our vision positioning system, it can effectively compensate for minor deviations in incoming materials and assembly, significantly improving production first-pass yield.

The Superior Performance of Guheng Energy’s Rocker-Arm Galvanometer Laser Welding Machine

Based on a deep understanding of the actual needs of battery PACK lines, Guheng Energy has innovatively launched a rocker-arm galvanometer laser welding machine, perfectly combining the high speed and flexibility of the galvanometer with the spatial freedom of a robot.

Innovative Design to Meet Flexible Production Line Needs

This equipment employs a unique rocker arm structure, with dimensions of 1280 mm in length and 780 mm in height, capable of supporting a weight of 9 kg and achieving a wide spatial coverage. This design is akin to equipping a high-speed galvanometer with a flexible “robotic arm,” freeing it from the limitations of a fixed light field. It can easily handle welding tasks for battery modules at different positions and angles, significantly saving production line space and improving equipment utilization.

Core functions optimized for battery module production:

Our equipment integrates several targeted optimization designs to ensure stable and efficient operation on the production line:

- Continuous adjustable power and fast switching response:The laser power is continuously adjustable within the range of ≤2000W and has a microsecond-level switching response speed. Combined with the F170 field lens, it can achieve fine welding of various materials and thicknesses, from thin nickel strips to thick aluminum foil.

- High stability and reliability:Utilizing a high electro-optical conversion efficiency laser and a built-in high-efficiency water cooling system, it ensures long-term stable laser output power, meeting the stringent production requirements of 24-hour continuous operation.

- Intelligent and easy-to-use:An integrated intelligent control system with a built-in database of aluminum-palladium welding and nickel sheet welding parameters verified by numerous processes. Operators can quickly access these parameters, reducing reliance on senior welding technicians. Simultaneously, the equipment supports real-time weld quality monitoring and data traceability, safeguarding product quality.

Practical Applications: How Guheng Energy’s Solutions Empower Efficient Production

Typical Welding Scenarios and Results

On actual battery PACK lines, Guheng Energy’s swing-arm galvanometer welding machine demonstrates its capabilities:

- In square aluminum-cased cell modules, it efficiently completes deep-penetration welding of the aluminum busbar and cell terminals, producing full, uniform welds with minimal heat-affected zones.

- In cylindrical cell modules, it quickly and accurately completes welding of numerous nickel connectors to cell tabs, with minimal welding spatter and a significantly improved yield.

- It performs 3D trajectory scanning welding on complex copper-aluminum composite busbars inside modules, showcasing unparalleled flexibility and precision.

Core Value for Customers

Choosing Guheng Energy’s solutions means customers gain more than just equipment; they gain a comprehensive upgrade in production efficiency and quality:

- Significantly Improved Efficiency:Welding speed is several times faster than traditional methods, effectively shortening production line cycle time and accelerating product delivery.

- Perfect Quality Assurance:Achieving near-perfect weld formation and a near-zero defect welding yield significantly improves the overall safety and cycle life of battery modules.

- Significant Cost Reduction:Reducing rework, scrap, and subsequent repair costs caused by poor welding, optimizing overall manufacturing costs.

- Enhanced Production Line Flexibility:Rapid production changeover capabilities easily address the market trend of multi-variety, small-batch production, helping customers respond flexibly to market demands.

Partnering with Guheng Energy: Towards a New Future of Intelligent Battery Manufacturing

The competition in battery module manufacturing is essentially a competition of precision, efficiency, and reliability. Galvanometer welding, especially Guheng Energy’s swing-arm solution, is becoming a key technology for breaking through current production bottlenecks and leading the next generation of battery manufacturing processes due to its unparalleled high speed, precision, and flexibility.

As a professional manufacturer specializing in providing new energy service technology solutions and battery maintenance and testing instruments, Guheng Energy always stays at the forefront of technology. We not only provide advanced equipment but also offer complete value chain support, including process development, production line integration, and ongoing services. We firmly believe that by combining innovative precision welding technology with deep industry knowledge, we can help every partner create safer, more efficient, and more competitive battery products. Let us join hands, driven by innovation, to propel the new energy industry toward a new era of intelligent manufacturing with higher quality and higher efficiency.

FAQ

Q: Why are porosity and cracks particularly prone to occur in aluminum-palladium welding?

A: The oxide film on the surface of aluminum hinders welding, and liquid aluminum easily absorbs hydrogen, generating porosity; its high coefficient of thermal expansion makes it prone to cracking due to shrinkage stress during solidification. Guheng Energy’s galvanometer welding machine, through special waveform control and optimized parameters, can stably break the oxide film and control the solidification process of the molten pool, effectively suppressing these defects.

Q: What are the main differences between galvanometer welding and ordinary laser welding on a battery production line?

A: The main differences lie in speed, flexibility, and tooling requirements. Ordinary laser welding relies on mechanical movement, is slow, and inefficient when the path is complex. Galvanometer welding achieves “flying welding” by deflecting the beam through a lens, resulting in extremely high speed, capable of instantly completing complex patterns, and is less sensitive to assembly gaps. Guheng Energy’s swing-arm design further expands its working space.

Q: How do you ensure good conductivity and low contact resistance when welding nickel sheets?

A: The key is to obtain a dense, defect-free weld. Precise control of heat input is required to avoid excessive burning. Guheng Energy’s equipment, through high-precision control of laser parameters, can form a full-bodied weld with uniform internal structure, ensuring a large and stable welding contact area, thereby guaranteeing excellent conductivity.

Q: Can Guheng Energy’s galvanometer welding machine be compatible with the production of battery modules of different models and sizes?

A: Absolutely. The swing-arm structure provides a wide three-dimensional working space, combined with the rapid scanning of the galvanometer, easily covering modules of different sizes. Intelligent software allows for quick switching of welding programs and parameters, achieving “one-click production changeover,” offering extremely high flexibility and making it ideal for multi-variety co-production.

Q: What is the biggest challenge when introducing galvanometer welding technology?

A: The biggest challenge is usually process parameter optimization and integration with new equipment. Guheng Energy not only provides high-performance equipment but also comprehensive process support. We have a mature welding process database, which can provide customers with verified initial parameters, and dispatch a professional team to provide a full range of services from production line planning, integration, and commissioning to personnel training, to ensure that customers can quickly achieve stable mass production.