In today’s rapidly developing new energy industry, battery packs, as core components, directly determine the final performance and market competitiveness of products through their production quality and efficiency. In the final line of defense before leaving the factory—off-line testing (EOL) and DC internal resistance (DCR) testing—every second of downtime means lost costs. Many battery manufacturers, especially automotive OEMs, are facing a common pain point: original equipment manufacturer (OEM) connectors have short lifespans and are easily damaged under the harsh conditions of frequent plugging and unplugging and high-current testing, not only slowing down production line pace but also incurring high maintenance costs. Today, we will delve into how Guheng Energy‘s contouring connectors have become an “essential tool” for breaking through this bottleneck and improving production line efficiency.

Why Have Traditional Connectors Become a “Drag” on Production Lines?

Ideally, production line testing should be as smooth as flowing water. However, the reality is that original equipment manufacturer (OEM) connectors, designed for the entire vehicle lifecycle, are simply unable to adapt to the high-frequency, high-intensity testing rhythm of production lines.

- Short lifespan and high cost: An OEM connector may only withstand a few hundred mating cycles. In the relentless testing of production lines, it can become worn out or fail completely within weeks or even days due to physical wear. Frequent replacements not only mean continuous investment in spare parts costs but also create enormous inventory management pressure.

- Low efficiency and impacted production line pace: Operators must carefully align and insert/remove connectors for each test, which is time-consuming and labor-intensive. If a connector experiences contact problems, it can lead to test interruptions, false data reports, and the need for retesting, severely impacting the first-pass yield (FPY) of the entire production line.

- Poor flexibility and slow response: Faced with rapidly iterating battery pack models, the long customization cycle and numerous restrictions of OEM connectors prevent production lines from quickly adapting to new projects, causing them to miss market opportunities.

The Core Value of Guheng Energy’s Contouring Connectors

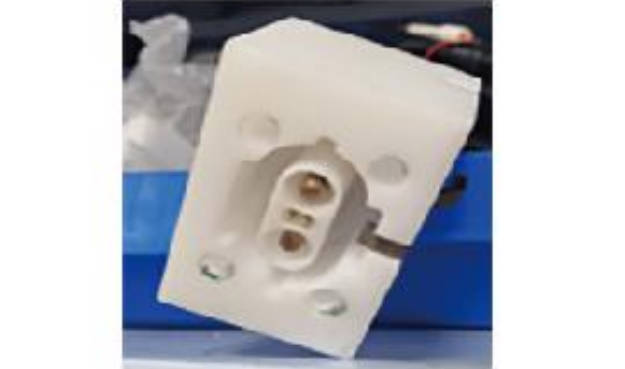

Addressing the aforementioned pain points, Guheng Energy, leveraging its deep technical expertise in new energy testing, has independently developed a series of contour connectors specifically designed for production line testing. Our design philosophy is clear: to upgrade connectors from fragile “consumables” to reliable “production tools.”

Core Advantage 1: Ultra-long lifespan, minimizing single-test costs

Lifespan is our primary consideration. Guheng Energy’s contour connectors utilize high-strength, high-temperature-resistant self-lubricating plastic shells and special alloy probes. Through precise design and rigorous testing, their mechanical lifespan can support over 3000 frequent mating cycles. This means that on most production lines, it can operate stably for months or even longer without replacement, minimizing the single-test cost of the connector and fundamentally solving the “unaffordable” problem.

Core Advantage 2: Modular architecture, revolutionizing maintenance

When the failure of a single component in a traditional connector leads to the entire connector being scrapped, we have introduced an innovative modular design: the probe module, shell, and other core components of the contour connector can be independently disassembled and replaced. If individual probes fail, maintenance personnel can replace them within minutes without any complex tools, restoring the equipment to its original condition immediately. This not only significantly reduces maintenance costs and downtime but also gives the equipment a longer lifespan.

Core Advantage 3: Deep Customization, Perfectly Fitting Testing Needs

We understand that no two battery packs have exactly the same test interface. Therefore, Guheng Energy provides a “one-to-one” professional customization service. Whether it’s square pins, round pins, or other special interfaces, we can perform precise conformal matching to ensure stable and safe connections. For example, for high-power DCR testing, our connectors can support a peak current of up to 500A while ensuring extremely low contact resistance and temperature rise, guaranteeing the accuracy of test data. For various signal acquisitions in EOL testing, we can also integrate communication interfaces for one-stop connection.

A Panoramic View of Guheng Energy’s Solutions

Our contour connector product line covers all scenarios for battery pack off-line testing:

- High-current DCR testing scenarios: We recommend using contour connectors like the 6402. Its powerful current-carrying capacity and robust structure are designed to handle high-current surges, making it an ideal choice for capacity testing port connections.

- Comprehensive EOL testing scenarios: For process tests involving multiple signals and low voltage/low current, contour connectors like the 4082 can perfectly replace original equipment manufacturer (OEM) connectors, enabling fast and stable cyclic testing.

- Complete wire harness solutions: Connector heads alone are not enough. We offer customized contour wire harnesses to match your needs. We can fully customize the wires, lengths, and mating devices according to your requirements, forming a complete, reliable, and efficient test interface solution.

In practical applications, a leading new energy vehicle OEM, after adopting Guheng Energy’s contour connectors and matching wiring harnesses, saw an 85% reduction in connector replacement frequency on its battery pack production line, virtually zero test interruptions due to connection issues, and an approximately 15% increase in single-shift testing efficiency, truly achieving cost reduction and efficiency improvement.

Conclusion

In the battery manufacturing field, which pursues ultimate efficiency and quality, every detail is crucial. Guheng Energy’s contour connectors may be just a small component on the production line, but they are a key link in ensuring smooth testing processes, accurate data, and controllable costs. It is not just a tool, but also our contribution of “efficiency and reliability” to the new energy industry.

We believe that choosing Guheng Energy means choosing a trustworthy partner. We are willing to work with you to overcome production line bottlenecks and empower your intelligent manufacturing future with innovative technology and tailored services.

FAQ

Q: What is the main advantage of contour connectors compared to the original connectors that come with the battery pack?

A: The main advantage is that they are specifically designed for high-frequency testing scenarios on the production line. Original equipment manufacturer (OEM) connectors focus on durability throughout the vehicle’s lifecycle, while Guheng Energy’s contour connectors, through reinforced materials and structural design, achieve an ultra-long mating life (over 3000 cycles). This fundamentally solves the core pain point of rapid connector wear and frequent replacements in production line testing, while also providing superior mating feel and stability, significantly improving testing efficiency.

Q: Does Guheng Energy’s contour connector support full customization? Is the customization cycle long?

A: Yes, we offer in-depth “one-to-one” customization services. You only need to provide the battery pack interface model or drawings, and we can perform precise contour manufacturing. Thanks to our mature modular design and rich project experience, we can achieve rapid response and delivery. For specific timelines, please consult our technical team for an assessment.

Q: What specific costs does modular design save us?

A: The cost savings from modular design are multifaceted. First, there are spare parts costs; only the damaged module needs to be replaced, not the entire connector. Second, there are time costs; modular maintenance is extremely fast, greatly reducing equipment downtime losses. Finally, regarding investment costs, when the test model changes, only some modules may need to be replaced instead of the entire equipment, protecting your initial investment.

Q: How do you ensure test accuracy when performing high-current DCR testing?

A: We ensure accuracy through two core measures: first, low contact resistance, using high-performance probes and special electroplating processes; second, excellent temperature rise control, through optimized current-carrying design and materials, ensuring minimal heat generation from the connector under high current, avoiding resistance changes due to temperature rise, thus laying the foundation for high-precision DCR measurement.