With the widespread adoption of new energy vehicles and energy storage systems, battery safety has become one of the most pressing concerns for consumers and manufacturers. If a battery pack experiences sealing failure during use, it can not only lead to performance degradation but also potentially cause short circuits, insulation degradation, and even fires, seriously threatening safety. Therefore, pre-shipment battery airtightness testing is the primary step in ensuring battery safety. As a professional provider of new energy service technology solutions, Guheng Energy is committed to providing battery manufacturers with fast and efficient pre-shipment testing solutions using advanced airtightness testing instruments, ensuring the reliability of every battery.

Why is battery airtightness so crucial?

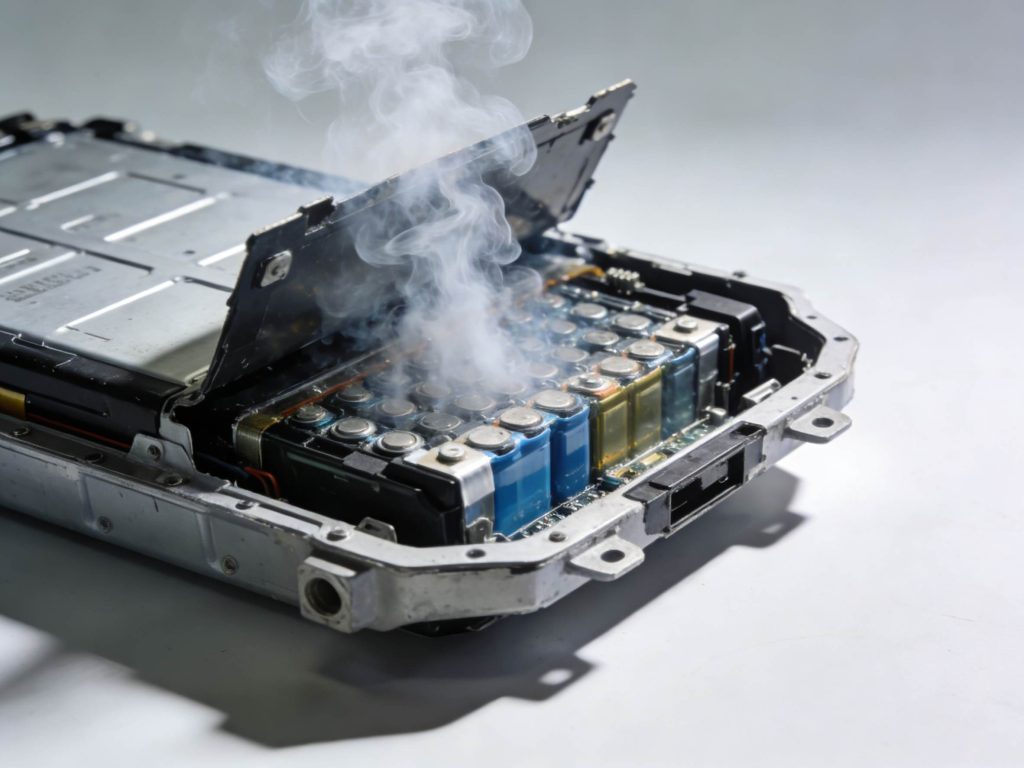

Safety Hazards of Sealing Failure

If a battery pack is not properly sealed, air and moisture can easily enter the battery, potentially causing various safety problems:

- Sealing failure allows moisture intrusion, causing a decrease in the internal insulation performance of the battery pack, thus significantly increasing the risk of short circuits.

- Moisture intrusion can cause side reactions with the electrolyte, producing corrosive gases that damage the SEI film on the electrode material, leading to lithium salt decomposition and metallic lithium deposition, thus accelerating capacity decay and shortening battery life. Oxygen intrusion can also exacerbate oxidation reactions.

- Long-term use damages the battery, reducing overall reliability and affecting the performance of the vehicle or energy storage system.

Quality Challenges in Production

Battery packs have complex structures and numerous sealing components, including module sealing, high and low voltage connectors, explosion-proof/pressure relief valve installation, and casing welding. Micro-leakage is difficult to detect manually or using traditional inspection methods, especially in large-scale production, where the risk of missed leaks increases significantly. This necessitates the use of professional and precise airtightness testing methods to ensure that battery packs leaving the factory meet safety standards.

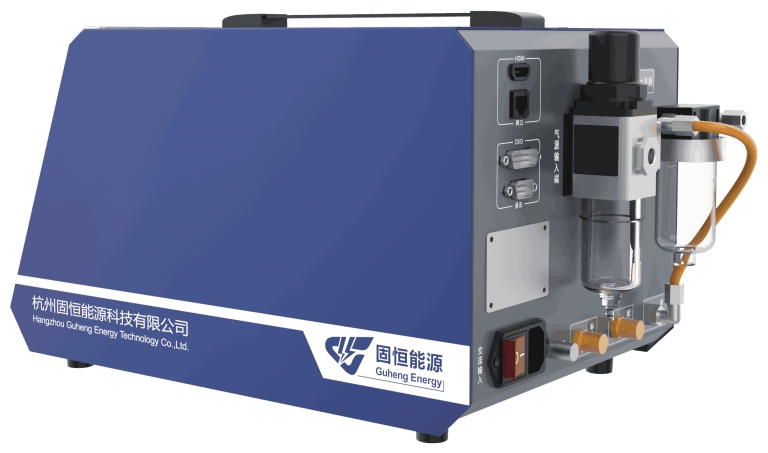

Guheng Energy QMM Series Portable Airtightness Leak Detector

To address the challenges of airtightness testing in production, Guheng Energy has launched the QMM series of portable airtightness leak detectors designed specifically for the new energy field. These detectors are suitable for airtightness testing of components such as liquid cooling plates, PDUs, FEUs, EDS, and battery boxes. This series of equipment utilizes Guheng Energy’s proprietary air pressure control technology, solving challenges such as automatic air pressure adjustment, air pressure stability, and high-precision sampling.

Main Features

- Precise Pressure Control: Patented air pressure control technology ensures automatic adjustment of the test air pressure to the most accurate value, improving detection accuracy.

- Liquid Protection: A unique liquid flow stop and independent exhaust path prevent liquid backflow from damaging the instrument (especially when testing components such as liquid-cooled plates that may contain residual coolant).

- Flexible Editing: Users can customize test procedures and parameters, and manage various test files.

- Report Generation: Built-in barcode scanner function instantly generates test reports.

- Multiple Interfaces: Supports multiple communication interfaces including I/O, RS485, and CAN.

- Customization Services: Provides professional airtight tooling design solutions for wider applicability.

- Portable and Easy to Use: Compact and lightweight structure, user-friendly interface, suitable for rapid on-site deployment.

Core Advantages

Guheng Energy’s QMM series portable leak detector offers the following core advantages in battery production:

- Rapid screening for sealing defects: Multiple batteries can be tested in a short time, ensuring product quality before shipment.

- Non-destructive testing: The testing process does not affect battery structure or performance.

- High precision and traceability: Test results are automatically recorded, facilitating production tracking and quality control.

- Enhanced corporate reputation: Rigorous testing ensures battery safety before shipment, enhancing customer trust.

Application of Battery Leak Testing in Production

Testing Process Overview

- Sample preparation: Place the battery pack to be tested on the testing platform and connect the leak detection interface.

- Testing operation: Start the QMM series portable leak detector and select the appropriate mode to monitor pressure changes.

- Data analysis and judgment: The instrument automatically generates a leakage curve and determines whether the battery is合格 (qualified/compliant) based on the set threshold.

- Result recording: Test data is saved to the system for easy traceability and analysis.

Comparison with Other Testing Methods

Traditional water testing methods (such as immersion) or pressure testing using simple instruments suffer from low efficiency, subjective result interpretation, and potential degradation of electrical insulation or component corrosion due to water immersion. In contrast, the QMM series instruments are easy to operate, non-destructive, and possess high-precision testing capabilities, capable of detecting minute leaks and significantly reducing the probability of missed detections.

Building the First Line of Defense for Battery Safety

By using the QMM series portable airtightness leak detectors in the production and shipping stages, companies can detect sealing problems at the earliest stage:

- Ensure batteries are protected from air or moisture during transportation and use.

- Prevent safety accidents caused by sealing defects.

- Gain market reputation and customer trust for the company.

Other Applications of Guheng Energy in Battery Safety

In addition to airtightness testing, Guheng Energy also provides several auxiliary products to enhance overall battery safety management:

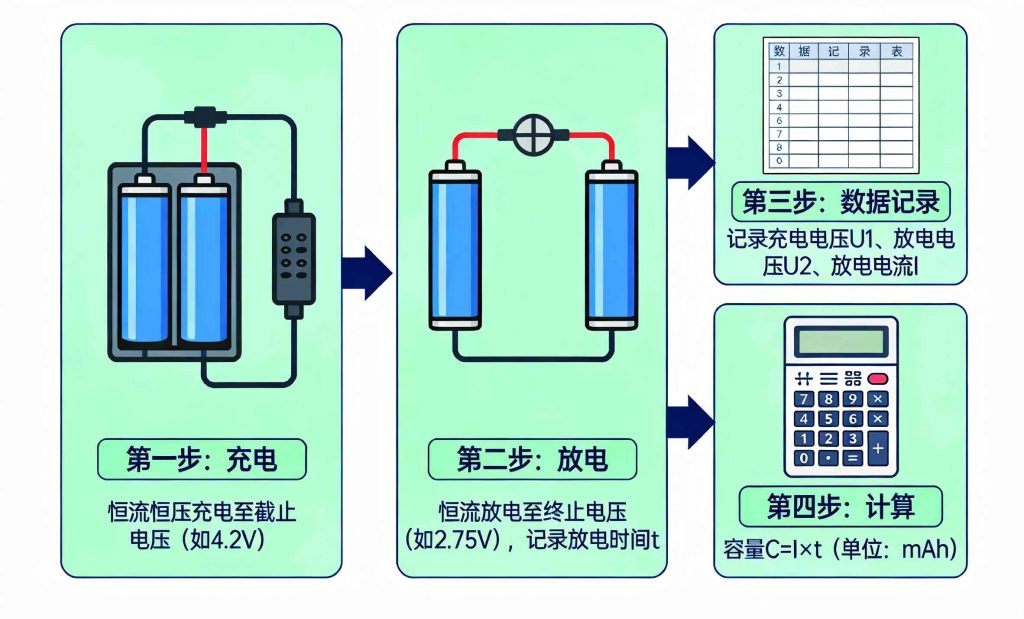

- Single-cell battery equalization and maintenance device: short-circuit and overvoltage protection, ensuring safe use.

- Portable Battery Maintenance Instrument: Supports battery capacity testing, equalization charging/discharging, and temperature monitoring.

- Insertion-type Gas Injection Fixture: Used for gas injection and sealing assistance in battery pack production, improving sealing reliability.

Through these products, Guheng Energy provides customers with a complete solution from production and testing to maintenance, forming a closed-loop management system and further reducing battery safety risks.

Conclusion

Battery airtightness is the cornerstone of ensuring the safety and performance of new energy products. By adopting Guheng Energy’s portable airtightness leak detector and related safety protection equipment, companies can comprehensively control battery quality before shipment, providing users with safe and reliable battery products. Choosing Guheng Energy is not only choosing high-precision testing, but also building a solid first line of defense for battery safety.

FAQ

Q: What is battery airtightness testing?

A: Battery airtightness testing uses specialized instruments to check whether the battery pack seal is intact, preventing air, moisture, etc., from entering the battery, ensuring battery safety and stable performance.

Q: Why must batteries undergo airtightness testing before leaving the factory?

A: Pre-shipment testing can quickly detect sealing defects, preventing safety accidents caused by water ingress, air ingress, or insulation degradation. It is a crucial step in ensuring battery reliability.

Q: What are the advantages of Guheng Energy’s portable airtightness leak detector?

A: This instrument is non-destructive, high-precision, and easy to operate. It can quickly screen defective batteries, improving production efficiency and the factory pass rate.

Q: Is airtightness testing applicable to all types of battery packs?

A: Yes, Guheng Energy’s airtightness detector can be applied to various new energy battery packs, including power batteries and energy storage batteries, ensuring the safety of different types of batteries.

Q: Can airtightness testing completely prevent battery fires?

A: While testing cannot completely eliminate all risks, it can significantly reduce the probability of fires caused by sealing problems, serving as the first line of defense for battery safety.