With the booming development of energy storage technology and the new energy vehicle industry, energy storage battery pack cells, as the core components of energy storage systems, directly impact system efficiency and safety due to their performance and lifespan. Proper daily maintenance not only extends the lifespan of cells but also ensures the stable operation of energy storage systems. This article provides a detailed overview of the basic knowledge of energy storage battery pack cells, the importance of maintenance, specific maintenance methods, and highlights the professional expertise of Hangzhou Guheng Energy Technology Co., Ltd. in the energy storage field, offering users a comprehensive maintenance guide.

Basic Knowledge of Energy Storage Battery Pack Cells

Composition and Role of Cells

Energy storage battery pack cells are the core components of battery packs, responsible for storing and releasing electrical energy. Their main components include:

- Positive Electrode: Typically made of lithium compounds (e.g., lithium iron phosphate or ternary materials), determining the battery’s energy density and voltage.

- Negative Electrode: Commonly made of graphite or silicon-based materials, affecting the battery’s cycle life and charging speed.

- Electrolyte: Acts as a medium for ion conduction, ensuring electrochemical reactions between the positive and negative electrodes.

- Separator: Prevents direct contact between the positive and negative electrodes to avoid short circuits while allowing ion passage.

- Casing: Protects internal components, typically made of aluminum or soft packs, requiring high airtightness and corrosion resistance.

Cells are combined in series or parallel to form battery packs, providing stable power for energy storage systems or electric vehicles. The performance of cells directly determines the capacity, lifespan, and safety of battery packs.

Characteristics and Applications of Different Cell Types

Commonly used cell types in energy storage battery packs include the following:

| Cell Type | Characteristics | Applications |

| Lithium Iron Phosphate (LFP) | High safety, long cycle life, low cost | Energy storage power stations, commercial electric vehicles |

| Ternary Lithium (NCM/NCA) | High energy density, excellent low-temperature performance | High-performance electric vehicles, portable energy storage devices |

| Lithium Titanate (LTO) | Ultra-long lifespan, fast charging/discharging, wide temperature range performance | Industrial energy storage, extreme environment applications |

Different cell types offer distinct advantages in energy storage scenarios, and users should select appropriate cells based on specific needs. For example, the Battery Pack Service Terminal Maintenance Tester BST-DW260 can accurately test various cell types, helping users optimize battery pack performance.

Importance of Daily Maintenance for Energy Storage Battery Pack Cells

Significance of Maintenance in Extending Battery Lifespan

Regular maintenance of energy storage battery pack cells is critical for extending their lifespan, with specific benefits including:

- Optimizing Cell Performance: Monitoring parameters like voltage and temperature to detect abnormalities promptly, ensuring cells operate in optimal conditions.

- Delaying Capacity Degradation: Proper charge-discharge management and cleaning maintenance slow cell aging, extending cycle life.

- Enhancing System Safety: Regular inspections prevent issues like cell overheating or short circuits, reducing safety risks.

For instance, lithium iron phosphate cells, with standardized maintenance, can achieve over 5,000 cycles, whereas neglecting maintenance may halve their lifespan.

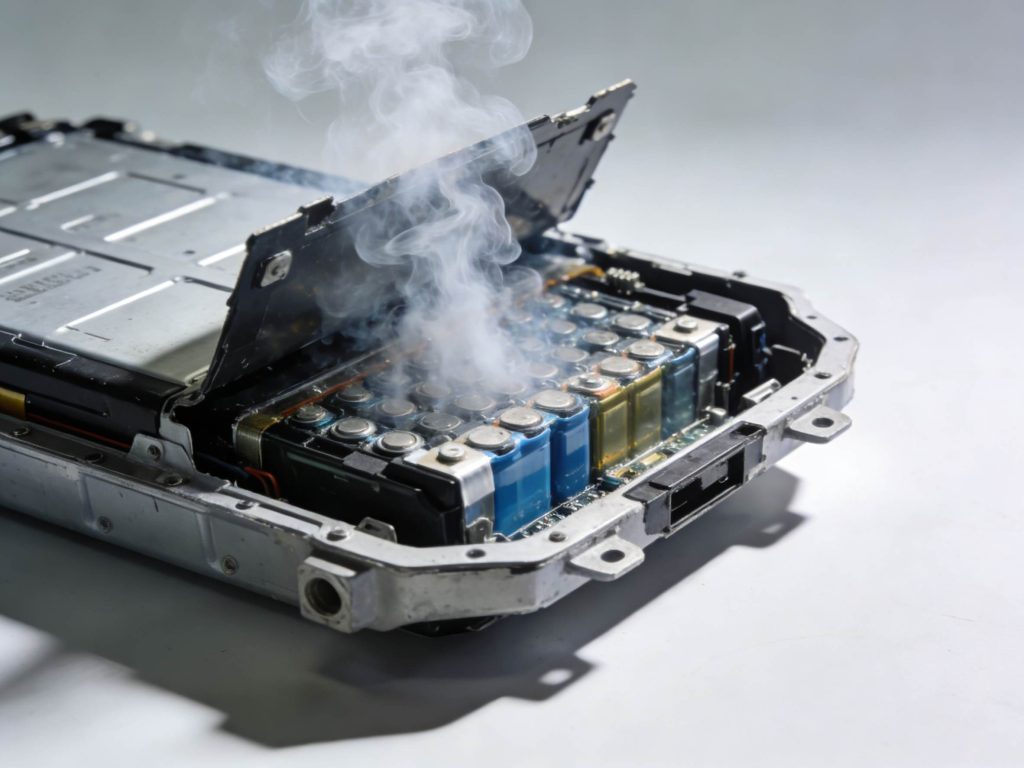

Problems Caused by Neglecting Maintenance

Failure to maintain cells can lead to the following issues:

- Rapid Capacity Degradation: Overcharging or over-discharging can damage the internal chemical structure of cells, reducing capacity.

- Safety Hazards: Cell overheating or electrolyte leakage may cause short circuits or even fires.

- Reduced System Efficiency: Inconsistent cell performance can lead to unstable overall battery pack output, affecting energy storage system efficiency.

- Increased Maintenance Costs: Undetected issues may escalate into serious faults, raising repair or replacement costs.

Thus, developing a scientific maintenance plan is key to ensuring the long-term stable operation of energy storage battery packs.

Daily Inspection and Maintenance Methods for Energy Storage Battery Pack Cells

Importance of Voltage and Temperature Monitoring

Voltage and temperature are critical indicators of cell health and require regular monitoring:

Voltage Monitoring:

- Ensure each cell’s voltage remains within the normal range (e.g., 2.5V–3.65V for lithium iron phosphate cells).

- Abnormal voltages may indicate increased internal resistance or capacity imbalance, requiring further inspection.

- Using the Battery Pack Service Terminal Final Inspection Instrument ETS-AE-100enables high-precision voltage testing.

Temperature Monitoring:

- Cell operating temperatures should be controlled between 15°C and 35°C to avoid accelerated aging at high temperatures or reduced performance at low temperatures.

- Install temperature sensors for real-time monitoring, with alarms for abnormalities.

Regular monitoring helps users identify potential issues early, preventing minor problems from escalating into major faults.

Regular Cleaning and Protective Measures

Cleaning and protection are essential aspects of cell maintenance, with specific measures including:

Cleaning Cell Surfaces:

- Use a dry cloth or specialized cleaning agent to wipe cell casings, removing dust and stains to prevent corrosion.

- Avoid using water-based or corrosive liquids to prevent damage to cell casings.

Inspecting Connection Components:

- Regularly check cell connection terminals and wires to ensure no looseness or oxidation.

- Apply anti-rust agents to exposed metal components to extend their lifespan.

Protective Measures:

- Store battery packs in dry, well-ventilated environments to avoid humidity or high temperatures.

- Use dust covers or sealed boxes to prevent dust and foreign objects from entering the battery pack.

Regular cleaning and protection can effectively reduce cell failure rates and extend battery pack lifespan.

How to Avoid Overcharging and Over-Discharging

Overcharging and over-discharging are primary causes of cell damage, and the following measures can prevent them:

Using a Battery Management System (BMS):

- A BMS monitors cell voltage and current in real-time, automatically cutting off circuits during overcharging or over-discharging.

- Ensure regular BMS software updates to adapt to different cell characteristics.

Setting Reasonable Charge-Discharge Ranges:

- Avoid charging cells to 100% or discharging to 0%; maintain a 20%–80% charge range.

- Perform shallow cycle charging periodically to reduce cell stress.

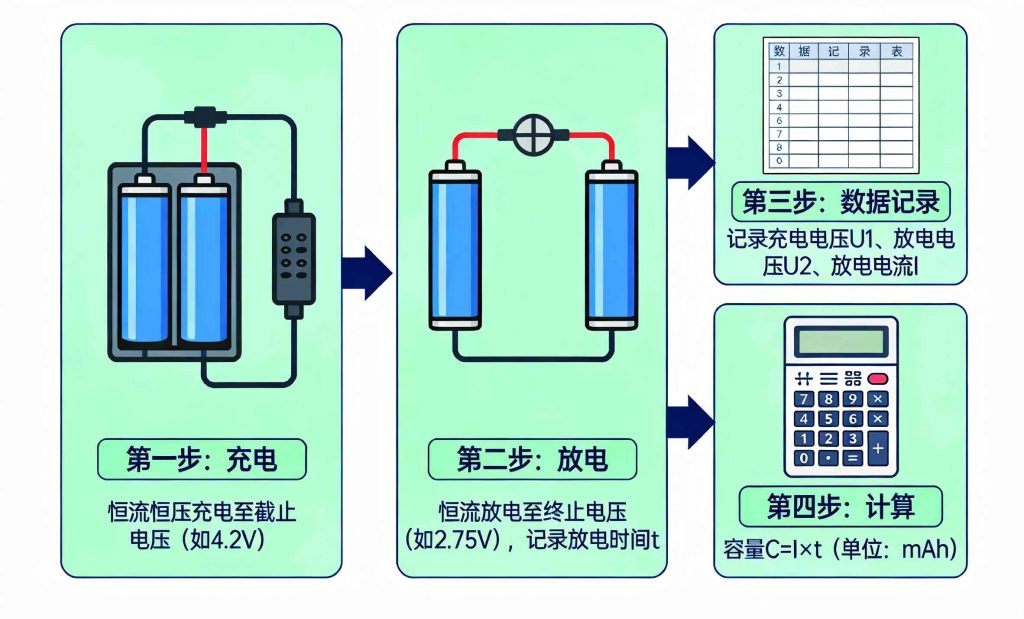

Regular Capacity Calibration:

- Conduct a full charge-discharge calibration every 3–6 months to optimize the BMS’s assessment of cell status.

Scientific charge-discharge management significantly extends cell lifespan and enhances safety.

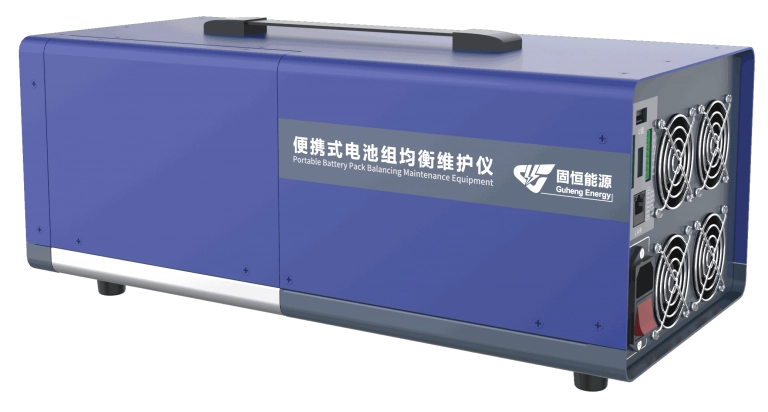

Guheng Energy: A Trusted Expert in New Energy Service Technology Solutions

Guheng Energy’s Professional Expertise in Energy Storage

Hangzhou Guheng Energy Technology Co., Ltd., established in 2012 and headquartered in Hangzhou, Zhejiang Province, is a national high-tech and specialized enterprise focused on technology development and services in the new energy sector. Guheng Energy demonstrates exceptional professional expertise in the maintenance and testing of energy storage battery pack cells:

- Technological Innovation: The company has developed several industry-first products, such as the Battery Pack Service Terminal Final Inspection Instrument (EOS-TEST) and the Battery Pack Service Terminal Maintenance Testing Instrument BST-DW260, widely used in energy storage system testing.

- Patent Portfolio: Holds over 30 patents (including 6 invention patents), 28 software copyrights, and multiple CE certifications, leading the industry in technical strength.

- Industry Contributions: Actively participates in setting energy storage industry technical standards, promoting the standardization of battery pack maintenance technologies.

Since its inception, Guheng Energy has served numerous well-known energy storage companies and new energy vehicle manufacturers, accumulating extensive industry experience.

Providing Comprehensive and Reliable Energy Storage Solutions

Guheng Energy leverages the following advantages to deliver comprehensive and reliable energy storage solutions:

- High-Quality Products: All equipment is certified under the ISO9001 quality management system, undergoing rigorous quality inspections and aging tests to ensure stable performance.

- Professional After-Sales Service: Provides 7×24 technical support with a dedicated team to respond quickly to customer needs, as detailed in Guheng Energy’s After-Sales Service.

- Customization Capabilities: Offers flexible equipment configurations and solutions tailored to diverse energy storage scenarios.

- End-to-End Support: Provides one-stop services from product design to after-sales maintenance, optimizing customer experience, as outlined in Guheng Energy’s Quality Management.

With its professional capabilities and customer-oriented service philosophy, Guheng Energy is a trusted partner in the energy storage industry.

Frequently Asked Questions

How to Determine If an Energy Storage Battery Pack Needs Replacement?

Determining whether an energy storage battery pack requires replacement involves evaluating the following indicators:

- Capacity Degradation: Measure the battery pack’s actual capacity using professional equipment. If capacity drops below 80% of the rated capacity, replacement is typically recommended.

- Increased Internal Resistance: Significant increases in cell internal resistance reduce charging and discharging efficiency, detectable via an internal resistance tester.

- Cycle Life: Refer to the cell’s technical specifications (e.g., approximately 5,000 cycles for lithium iron phosphate cells). If the cycle life is nearing or exceeding its limit, replacement is advised.

- Abnormal Symptoms: Frequent overheating, abnormal voltage fluctuations, or physical deformation require immediate inspection and possible replacement.

Regular comprehensive testing by professional institutions is recommended to ensure accurate assessments. Ignoring abnormalities may lead to system failures or safety incidents.

What Precautions Should Be Taken When Energy Storage Battery Packs Are Idle for Long Periods?

Long-term idleness of energy storage battery packs can lead to self-discharge and cell aging, requiring the following precautions:

Storage Environment:

- Store in a dry environment with temperatures between 15°C and 25°C and humidity below 60%, avoiding high temperatures or moisture.

- Keep away from fire sources and corrosive substances to ensure storage safety.

Charge Management:

- Maintain cell charge levels at 50%–60%, avoiding full discharge or full charge during storage.

- Perform a shallow charge-discharge cycle every three months to activate cell activity.

Regular Inspections:

- Check cell voltage and appearance every six months, recording data to monitor health status.

- Use professional equipment (e.g., Guheng Energy’s maintenance testing instruments) to test cell internal resistance and capacity.

BMS Maintenance:

- Ensure the BMS is powered off to prevent long-term operation wear.

- Update BMS firmware before reactivation to optimize performance.

Scientific storage and regular maintenance minimize the impact of idleness on cell performance.

Can Energy Storage Battery Packs Be Disassembled for Repairs by Users?

Generally, users are not advised to disassemble energy storage battery packs for repairs due to the following reasons:

- Safety Risks: Battery packs contain high-voltage cells and electrolytes, and improper disassembly may lead to electric shock, short circuits, or electrolyte leakage, causing fires or explosions.

- Professional Requirements: Cell repairs require specialized equipment (e.g., internal resistance testers, voltage calibrators) and trained technicians, which typical users lack.

- Warranty Implications: Unauthorized disassembly may violate manufacturer warranty terms, voiding after-sales service eligibility.

- Complexity: Battery pack structures are intricate, involving multiple cell groups and BMS coordination, and non-professional repairs may degrade performance or cause system failures.

Users encountering issues should contact professional service providers for testing and repairs. Guheng Energy provides comprehensive maintenance support to ensure battery pack safety and performance.