With the rapid development of new energy technologies, energy storage battery packs have become the core equipment for home energy storage, industrial and commercial backup power, and other scenarios. However, the problem of battery performance degradation over time has always troubled users. How to extend battery life through scientific maintenance methods? This article will deeply analyze the maintenance points of energy storage battery packs and focus on Charge and discharge maintenance instrumentcore value.

1. Working principle and core composition of energy storage battery pack

- The energy storage battery pack realizes energy storage and release through electrochemical reaction. Its core consists of the following three parts:

- Battery cell: As an energy carrier, lithium-ion batteries complete charging and discharging through the migration of lithium ions between the positive and negative electrodes;

- Battery Management System (BMS): real-time monitoring of voltage, temperature and other parameters to ensure safe operation of the system;

- Thermal management system: Maintain optimal operating temperature (25℃±5℃) through air cooling/liquid cooling device.

- There are two key indicators to pay attention to during the charging and discharging process:

- Cycle Life: A battery undergoes a complete charge and discharge (0%-100%), which is a cycle.

- Depth of discharge (DOD): It is recommended to control it within 80% on a daily basis. Deep discharge (>90%) will accelerate the loss of electrode materials.

2. Four major culprits of energy storage battery pack aging

- Physical limitations of cycle life

The theoretical cycle life of lithium batteries is 3000-5000 times, but in actual applications the following factors will accelerate aging:

- Over-discharge: A charge lower than 20% for a long time will cause the negative electrode SEI film to rupture;

- Overcharge risk: When the voltage exceeds 3.7V/cell, lithium dendrites may precipitate, causing a short circuit;

- Temperature out of control: For every 10°C increase in temperature above 35°C, the capacity decay rate increases by 2 times.

- Hidden injury factors

- BMS system failure causes single cell voltage imbalance;

- The “passivation effect” caused by long-term idleness;

- “Virtual cycle loss” caused by high-frequency shallow charging and discharging.

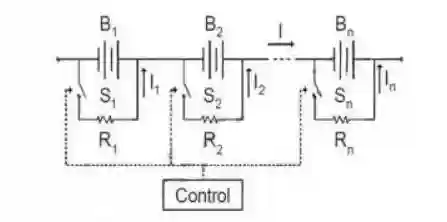

3. Battery Balancing Principle

balancedThe principle ispassindependentRegulates battery current flow,Whole GroupThe voltage difference of the battery is reduced to a minimum, thus achieving charge balance, improve the actual capacity of the entire battery andCycle life.There are two common balancing methods: active balancing and passive balancing. Active balancing achieves balancing by injecting current or discharging certain batteries in the battery pack; passive balancingGenerally refers toYes ControlResistor switch for battery cellsThe discharge process is used to achieve equilibrium.

Active equalization equivalent diagram Passive equalization equivalent diagram

4. Balance maintenance instrument: “regeneration engine” of battery life (taking PBM-PW-B-4805 as an example)

1. The main functions of the balancing machine maintenance instrument are:

- Adopting proprietary parallel charge and discharge control technology to ensure the high consistency of charge and discharge effects of each channel;

- Adopt modular design and use independent and fully functional charging and discharging modules;

- Support channel gating, voltage cutoff, capacity cutoff and other functions;

- Support three working modes: parallel charging maintenance, parallel discharge maintenance and balanced maintenance;

- Support independent and series working modes of balancing units;

- Support depolarization processing at the end of maintenance to improve maintenance effect;

- Supports storage of maintenance data for each channel;

- High reliability, supporting multiple protections;

- Small size, light weight, easy to carry

2. Performance Data

- Regular maintenance can reduce battery capacity decay by 40%;

- Balanced maintenance reduces the difference in internal damage of the battery pack and extends the overall life by 30%.

5. A complete guide to the operation of the balance maintenance instrument

1. Balanced wiring harness connection method:

- Conventional alligator clip harness

Connect the cells in order according to the label information on the wiring harness, and then collect the voltage information of the single cell;

- Custom balanced wiring harness

Connect the customized BMS balancing port or module voltage collection port to collect the voltage information of each single cell;

2. Equipment operation:

- Turn on the device power, the number of strings and extreme values on the main page are displayed correctly, click Device Parameter Settings (Figure 1), enter the parameter setting interface, enter the required parameter data, and click Download Parameters (Figure 2) to save the parameters;

Figure 1 Figure 2

- Click the start button on the main page, the device will self-check first, and after the self-check is completed, the device will perform normal maintenance work (Figure 3);

Figure 3

3. Safety protection points

- First of all, equipment maintenance is very important for the normal use and life extension of the equipment. Maintenance includes cleaning, lubrication, inspection and repair of the equipment. During the use of the equipment, the equipment should be cleaned as necessary to remove dust and dirt on the surface of the equipment.Harsh environment(dust) When using the equipment, protective measures should be taken to prevent dust from entering the equipment and affecting its normal operation. At the same time, the equipment needs to be lubricated regularly to reduce equipment wear and friction and improve equipment operating efficiency. In addition, the equipment should be inspected regularly to promptly detect equipment failures and problems, contact our company for repairs and replacement of parts to ensure the normal operation of the equipment.

- Secondly, the storage environment and conditions of the equipment should be taken into consideration. The equipment should be stored in a dry, ventilated place with good lighting conditions to prevent moisture and heat from affecting the service life of the equipment. At the same time, the place where the equipment is stored should be away from flammable, explosive and corrosive substances to ensure the safety of the equipment. In addition, it is also necessary to avoid storing the equipment for a long time without using it for a long time to avoid problems such as rust, deformation and aging of equipment parts.

- For example, the equipment users need to undergo professional training and be familiar with the equipment’s operating procedures and precautions. The operating procedures should be followed during the use of the equipment, and improper operation of the equipment is prohibited;

4. Solid Energy Technological breakthroughs in intelligent maintenance solutions

As an industry-leading energy storage solution provider,Solid EnergyofPBM-PW Series Maintenance InstrumentWith three major innovations:

- Balancing algorithm strategy: automatically identify battery aging patterns and match repair strategies;

- Cloud platform management: remote maintenance record tracing is achieved through IoT module.

The measured data of a commercial and industrial energy storage project showed that after using the maintenance instrument, the annual capacity decay rate of the battery pack dropped from 8% to 3.2%.

In conclusion

Through the scientific use of the balancing maintenance instrument, users can shorten the investment return period of the energy storage system by 18-24 months. Guheng Energy recommends that standardized maintenance be performed quarterly and capacity calibration tests be performed regularly. Choosing professional-grade maintenance equipment not only protects battery assets, but also provides technical support for achieving carbon neutrality goals.