How can a seemingly insignificant problem lead to major trouble?

In today’s rapidly developing new energy industry, battery modules, as the core of power and energy storage, directly determine product performance, lifespan, and safety through their assembly precision. However, in production and maintenance, a seemingly trivial step—the assembly of the voltage sampling harness—often becomes the Achilles’ heel, causing significant risks. A misconnected harness or a disordered wiring sequence can lead to malfunctions in the Battery Management System (BMS), resulting in serious safety and performance risks.

As a provider of new energy technology solutions, Guheng Energy understands that true quality stems from meticulous control over every detail. Today, we will delve into the dangers of incorrect wiring sequences and reveal how we, with our BWT series battery voltage acquisition instruments, achieve “zero-error” detection from the source, safeguarding your safety and efficiency.

A Small Difference, a Vast Error: The Deep-seated Hidden Dangers of Incorrect Battery Module Wiring Sequence

What is incorrect battery module wiring sequence?

Simply put, it refers to the wiring harnesses connecting the battery cells (cells) to the BMS (Battery Management System) for voltage and temperature sampling (such as NTC) not being connected in the correct order according to the design drawings during battery module assembly. This may manifest as two wires being reversed, the entire assembly being connected in reverse, or even individual channels being crossed, causing the signals received by the BMS to be completely inconsistent with the actual physical state of the battery.

The Chain Reaction and High Costs of Incorrect Wiring Sequence

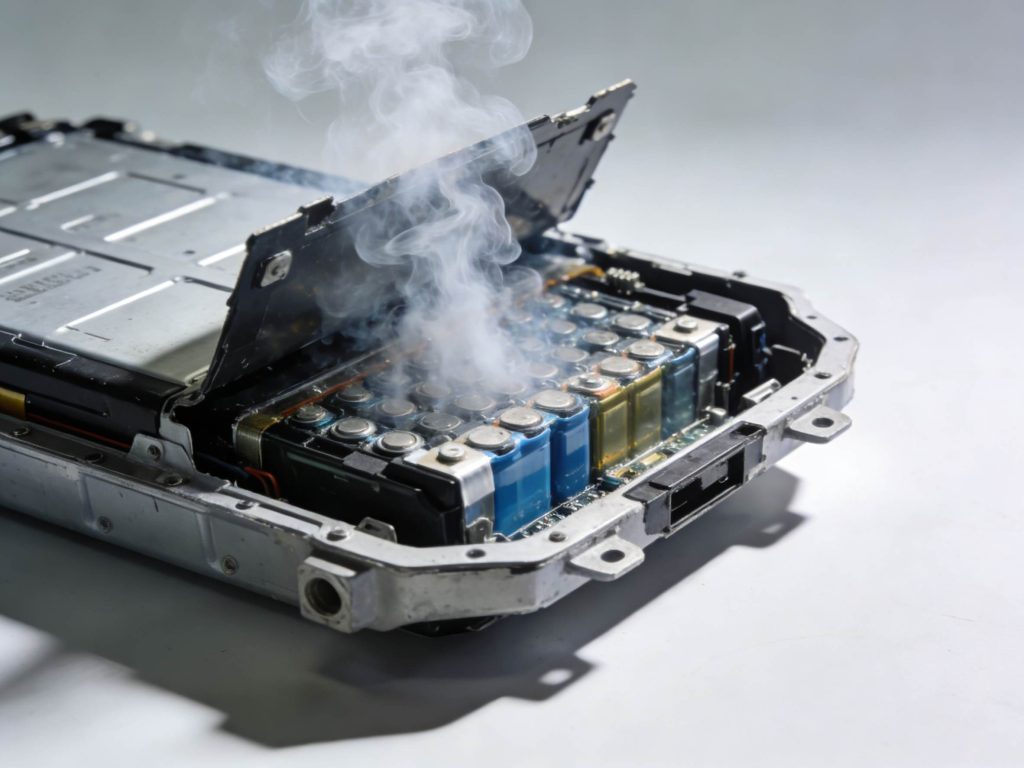

- Safety Risks: Distorted data can lead to incorrect battery state estimations by the BMS. For example, when a cell with a high actual state of charge (SOC) is misjudged as having a low SOC, the BMS may instruct it to continue charging, easily causing overcharging, leading to thermal runaway, and ultimately resulting in serious consequences such as short circuits, fires, or even explosions.

- Performance Degradation and Sharply Reduced Lifespan: Incorrect wiring sequence will disrupt the balance of the battery pack. The BMS (Battery Management System) cannot effectively manage battery balancing based on actual voltage, causing some cells to be in a state of overcharging or over-discharging for extended periods. This leads to a sharp decline in the overall battery capacity and a significant reduction in lifespan.

- Unbearable Efficiency and Costs: For battery manufacturers, this means the shutdown of the entire production line, heavy rework, high scrap costs, and delivery delays. For auto repair shops, incorrect installation can damage new modules, leading to customer complaints and even greater economic losses.

Solution:Guheng Energy’s BWT Voltage Acquisition Instrument’s “Sharp Eyes”

Addressing the pain points of traditional multimeter manual testing—such as low efficiency, fatigue, and the tendency to miss detections—Guheng Energy is committed to reshaping testing standards with automated and intelligent solutions. Our BWT series battery voltage acquisition instrument is designed to eliminate wiring sequence errors. This device combines high speed, high precision, and intelligence. Its core principle is to move quality control upstream, shifting from relying on post-event remediation to source prevention, thereby effectively improving the first-pass yield (FPY).

Unveiling the Core of “Zero Error”: How BWT Achieves Precise Wiring Sequence Verification

The “zero error” detection of the Guheng Energy BWT voltage acquisition instrument is not just a slogan, but a product of a series of robust technical functions.

Automated Scanning and Instant Comparison

The device supports synchronous or high-speed sequential voltage acquisition from hundreds of channels and compares the acquired data with the correct wiring sequence model preset by engineers within milliseconds. Once a mismatch is detected, an alarm is triggered immediately without any delay.

Intelligent Algorithm Identifies Abnormal Patterns

The built-in diagnostic algorithm can identify various fault modes, not only determining basic faults such as open circuits and short circuits, but also accurately diagnosing complex wiring errors such as reverse polarity connection and channel cross-connection, and precisely locating which two channels are faulty.

Visual Alarm and Precise Location

The device is equipped with a 2.8-inch TFT high-definition LCD touchscreen with an extremely user-friendly interface. When a wiring sequence error is detected, the screen will clearly indicate the location and type of error with bright colors (such as red highlight) and text prompts. Meanwhile, users can customize sound alerts for different test results, leaving no room for problems to hide.

Data Recording and Quality

Traceability Detailed data from each test, including voltage values, temperature values, and wiring sequence verification results, can be automatically saved via the built-in USB flash drive. This provides an immutable data chain for product quality traceability and production data analysis, a crucial link in achieving digital quality management.

Practical Application: The Value Enhancement Brought by Guheng Energy’s BWT Voltage Acquisition Instrument

Long-term Returns, Beyond Testing Investing in a BWT voltage acquisition system is more than just purchasing equipment; it’s introducing an efficient and reliable quality control system. The cost savings from rework, the safety precautions taken, and the enhanced brand value it provides will bring a return on investment far exceeding expectations.

- For battery manufacturers: Introducing BWT for full inspection at the end of the battery pack assembly line ensures 100% correct wiring sequence for every module leaving the factory. This significantly improves first-pass yield, reduces after-sales risks, and strengthens the company’s brand reputation.

- For auto repair shops: When replacing battery modules, using BWT for final verification of the repaired modules ensures absolutely correct installation, avoiding secondary damage or customer disputes caused by operational errors, and enhancing the professionalism and reliability of the repair shop.

Choose Guheng Energy, choose a foolproof starting point

In the new energy field, where ultimate safety and efficiency are paramount, even the smallest oversight can lead to irreparable losses. Guheng Energy, with its solid technology and reliable testing products, is committed to becoming a trusted partner for its customers. Our BWT series battery voltage acquisition systems are designed to eliminate the risk of incorrect wiring sequences from the source, ensuring accurate assembly every time and safe and reliable battery packs every time.

FAQ

Q: Is Guheng Energy’s BWT battery voltage acquisition system compatible with battery modules of different brands and models?

A: Yes, compatibility is a key design focus. The BWT series supports flexible settings for the number of battery strings and NTCs, and supports various specifications of NTC thermistors, with configurable B-values (Beta values) or Steinhart-Hart coefficients to adapt to different temperature calculation models. Users can easily configure various thresholds such as voltage and temperature via the touchscreen, thus widely adapting to most brands and models of battery modules on the market and meeting diverse needs.

Q: Will using BWT for line sequence testing significantly reduce production cycle time?

A: Absolutely not. BWT is designed to improve efficiency. It can complete the automated scanning and verification of all measurement points of the entire module within one or two minutes, far exceeding the speed of manual point-by-point measurement. This not only does not slow down the cycle time, but also significantly improves the overall output efficiency of the production line by eliminating rework.

Q: Besides line sequence testing, what other functions does the BWT voltage acquisition unit have?

A: BWT is a multi-functional integrated platform. In addition to the core line sequence verification, it also supports testing the voltage uniformity of battery modules (to determine cell consistency) and NTC temperature probe performance testing. In addition, Guheng Energy also provides complete supporting solutions, such as the GD series airtightness tester for battery pack airtightness testing and a professional insulation tool kit for maintenance operations, forming a comprehensive quality and safety protection network.

Q: Is the instrument complicated to operate? Does it require a high level of technical skill from the operators?

A: It’s very simple. We adhere to a “human-centered” design philosophy. The 2.8-inch TFT high-definition LCD touchscreen makes all operations clear at a glance. The testing process can basically be started with one click, and the results are automatically determined. Operators do not need a deep technical background; they can quickly get started after brief training, effectively reducing the company’s reliance on highly skilled workers and the risk of human error.