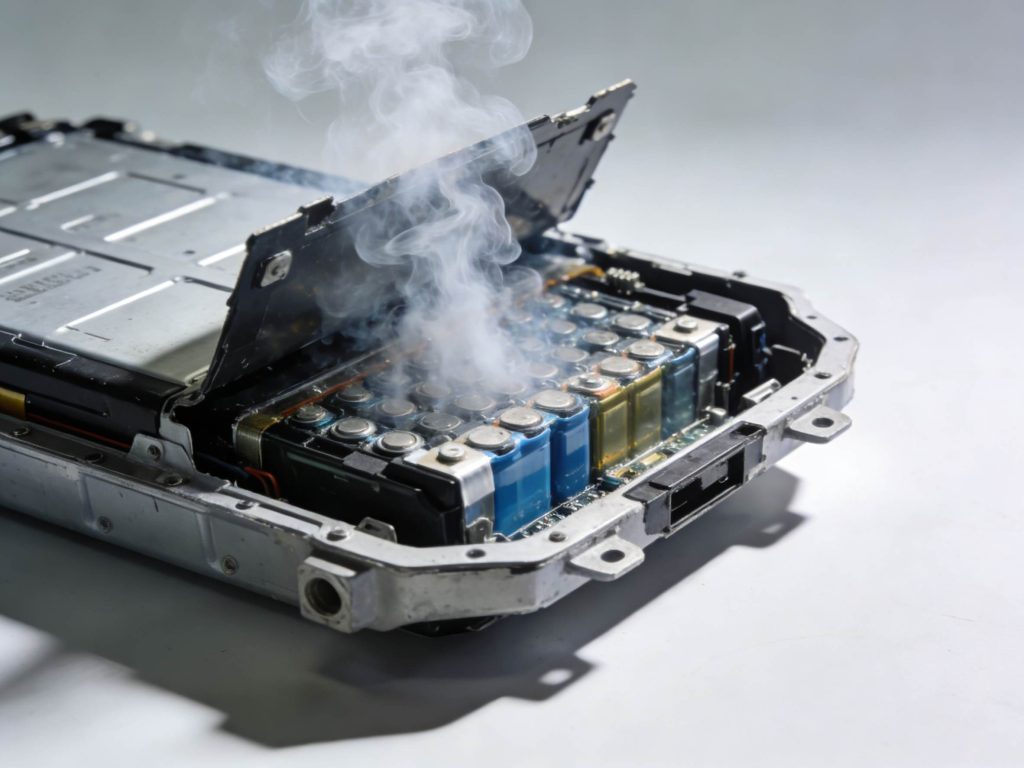

In recent years, with the rapid development of the new energy vehicle industry, related safety issues have frequently sounded the alarm. Many shocking fire accidents not only occurred during vehicle operation or charging but also exposed a severely underestimated risk factor—when power batteries are stored in repair workshops, inspection areas, or storage warehouses in the form of “battery packs” or “battery modules,” their potential “thermal runaway” risk is not dormant.

These batteries, in a non-operating state, may catch fire and explode without warning due to internal hidden damage or external environmental factors. Faced with such unpredictable and sudden risks, relying solely on personnel management standards and operating procedures is particularly vulnerable. Specialized venues must build a solid and reliable physical protection line to isolate risks within a controllable range; this is the cornerstone of ensuring fire safety in scenarios such as “auto repair service stations” and “battery factories.”

The Overlooked “Silent” Risk: Why are Batteries More Dangerous During Storage and Maintenance?

Risk Scenarios Focus: Hazard Concentration Points in Non-Operating States

In many specialized scenarios, clusters of batteries in a “non-operating state” constitute high-risk areas:

- Auto Repair Service Stations: Battery packs removed from accident or faulty vehicles are often piled up in a corner of the repair area or a designated temporary storage area. These batteries may already have internal structural damage or cell short circuits, and the risk continues to accumulate while they remain idle. Battery packs undergoing repair at workstations are also exposed to the open environment.

- Battery Manufacturing Plants: Large numbers of battery modules are stored together at the end of the production line, in the pre-shipment inspection area, and in areas specifically for storing rework and defective products. Thermal runaway in any one unit could trigger a catastrophic chain reaction.

- Energy Storage Power Station Operation and Maintenance Sites: During battery maintenance or replacement operations, replaced old modules are often temporarily piled up, and even slight negligence in management can create blind spots for safety risks.

Risk Root Cause Analysis: A Dual Combination of Internal and External Factors

The root causes of risks associated with stationary batteries are complex and hidden:

- Invisible Internal Damage: After a collision, the internal electrodes and separators may have undergone micro-deformation or minor short circuits. This damage is difficult to detect in routine testing, but when stationary, the internal short circuit points may continue to generate heat, eventually leading to thermal runaway.

- External Environmental Induction: Dense stacking hinders heat dissipation, excessively high ambient temperatures, or accidental short circuits at the terminals during handling can all easily become the “trigger” for thermal runaway.

- Limitations of Management Measures: While regulations and personnel training are important, they cannot monitor the chemical state and temperature changes inside each battery in real time, nor can they prevent the spread of flames in the instant a fire breaks out. By the time the alarm sounds, the fire is often already out of control.

Building the First Line of Physical Defense: From “Management Protection” to “Intrinsic Safety”

The Core Value of the Physical Defense Line: Isolation and Suppression

Faced with a sudden battery fire, the most effective strategy is “isolation” and “early suppression.” This introduces the concept of “inherent safety” enhancement—by adding hardware facilities with specific protective properties, the source of danger is fundamentally isolated from personnel, other assets, and the environment. Even if a disaster occurs internally, it can be contained within a certain space, buying crucial time for emergency response. This last line of defense is the bottom line for protecting lives.

Key Requirements for Professional Protective Facilities

A qualified physical protective facility specifically designed for power batteries must meet several stringent requirements:

- Extreme fire resistance integrity: Its cabinet structure must be able to withstand the ultra-high temperature flames (typically exceeding 1000°C) generated by the thermal runaway of the power battery for an extended period, ensuring that flames and high-temperature smoke do not penetrate the cabinet before firefighters arrive.

- Proactive early intervention capability: It needs to integrate a highly sensitive detection system and automatic fire extinguishing device, capable of automatically activating suppression programs in the very early stages of a fire to extinguish or control the initial fire.

- Targeted Design: The design must be specifically tailored to the size, weight, fire characteristics (spray fire, reignition), and potential toxic gases produced by the power battery pack/module. Ordinary document safes or chemical storage cabinets are completely ineffective.

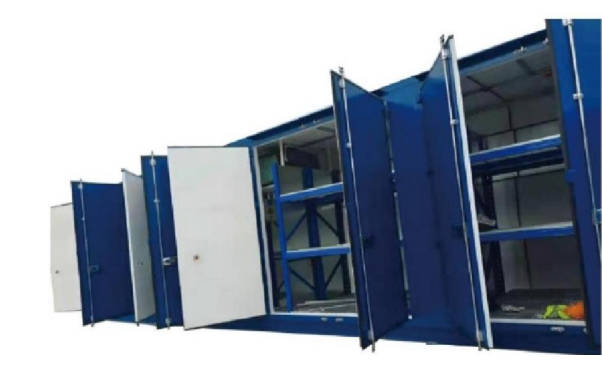

Guheng Energy Fixed Power Battery Safety Storage Cabinet: An Integrated Safety Solution

As a technology solution provider specializing in safety risk management in the new energy field, Guheng Energy deeply understands industry pain points and has developed a professional fixed power battery safety storage cabinet. This cabinet aims to provide an integrated solution combining “active defense” and “passive isolation” for critical scenarios.

Impregnable Passive Protection: Fire Integrity Greater Than 90 Minutes

The core fortress of this storage cabinet is its superior cabinet structure. The cabinet frame uses high-strength steel and undergoes special design and treatment to ensure its fire integrity is greater than 90 minutes. This means that even if the batteries inside the cabinet experience the most intense combustion, the flames and high temperatures will not be able to burn through the cabinet walls for more than 90 minutes. These precious 90-plus minutes were sufficient for the safe evacuation of personnel, activation of the emergency response plan, and waiting for professional firefighting forces to handle the situation, effectively preventing the fire from spreading and escalating within the storage area and causing a catastrophic chain reaction. The bottom of the cabinet is also equipped with a steel liquid collection tray with an anti-corrosion coating to collect any potential leaks.

Rapid Response Active Defense: Fire Alarm and Closed-Loop Sprinkler System

Passive protection is the bottom line, but active intervention is key to minimizing losses. Guheng Energy’s safe storage cabinet integrates an intelligent fire alarm and a closed-loop fire sprinkler system, forming a dual active defense line:

- Intelligent Fire Alarm System: Equipped with high-sensitivity detectors, the cabinet can monitor abnormal parameters such as temperature and smoke in real time. Once early signs of thermal runaway are detected, a high-volume audible and visual alarm is immediately triggered, alerting on-site personnel to take emergency measures.

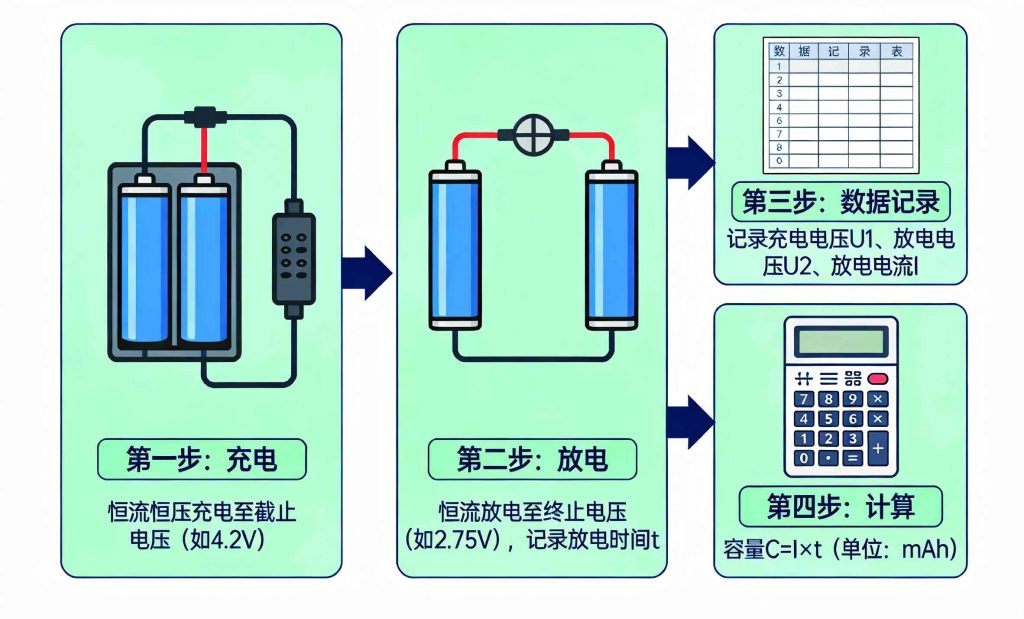

- Closed-Loop Fire Sprinkler System: This is an effective means of dealing with battery fires. The system piping is filled with water, and the sprinkler heads are designed in a closed loop. When the internal temperature of the cabinet rises to the nozzle’s activation temperature, the glass bulb of the closed nozzle ruptures due to heat, and water immediately sprays towards the fire source, directly cooling and extinguishing the burning battery module. Water can quickly absorb a large amount of heat, effectively curbing heat spread and preventing a single cell failure from escalating into a disaster for the entire battery pack. The system is also equipped with an automatic drainage device for draining accumulated water after fire suppression, facilitating maintenance and rapid restoration of the facility to normal operation.

Comprehensive Safety and Customized Design

In addition to its core fire prevention and extinguishing functions, this storage cabinet also reflects thorough attention to detail:

- Environmental Control: Optional ventilation devices and even explosion-proof air conditioning can be added to regulate the air and temperature inside the cabinet, providing a more stable temporary storage environment for the batteries and reducing risks from the source.

- Pressure Relief and Monitoring: The cabinet is equipped with a pressure relief valve to release high-pressure gas generated during a fire, preventing physical explosions. It also supports optional intelligent modules such as video monitoring and online battery compartment temperature monitoring for remote safety supervision.

- Flexible Customization: We understand that different scenarios have different needs. Guheng Energy supports product customization. Whether it’s size, internal battery storage rack layout, or the addition or removal of specific functional modules, it can be flexibly configured according to the specific needs of “auto repair service stations” or “battery factories,” providing a truly scenario-specific physical protection solution.

Towards a Safer Future: Building a Safety Culture in Professional Venues

Building a safety culture requires the joint efforts of everyone in the industry. Guheng Energy‘s safety storage cabinets are a powerful hardware foundation for building a safety system in professional venues. However, true safety comes from the deep integration of “human, technical, and physical protection.” We recommend:

- Incorporating physical protection facilities into safety standards: Companies should explicitly list professional battery safety storage equipment as a mandatory safety configuration for high-risk work areas in their risk assessments.

- Establishing strict operating procedures: Even with safety cabinets, management processes such as battery entry and exit registration, status checks, and storage duration must be standardized.

- Strengthening employee safety training: Every employee should understand battery risks, master emergency procedures, and know how to properly respond when an alarm sounds.

Conclusion

The risks of leaving power batteries in a static state are like a dormant volcano, not to be underestimated. For professional locations such as auto repair shops and battery factories that house large numbers of batteries, proactively deploying reliable physical safety measures is no longer an “optional option,” but a “must-have” for survival and responsibility.

Guheng Energy is committed to building a solid safety foundation for its partners through professional and reliable technical solutions. Our fixed power battery safety storage cabinets, with over 90 minutes of fire resistance and an intelligent active suppression system, provide you with the first and most critical physical defense against sudden fires. Let us join hands and use the power of technology to drive the new energy industry towards steady, sustainable, and high-quality development while ensuring safety.

FAQ

Q: Can ordinary fireproof safes store power batteries?

A: Absolutely not. Ordinary fireproof safes are designed for fires involving paper and cannot withstand the sustained high temperatures (above 1000°C) and potential explosive impacts caused by thermal runaway of power batteries. They also lack early detection and suppression systems for battery fires. Specialized equipment designed specifically for safe battery storage must be used.

Q: Is it safe to use water to extinguish battery fires in the closed-loop sprinkler system of Guheng Energy’s safety storage cabinet?

A: This is a crucial point. For initial and small-to-medium-scale battery fires, water is a very effective cooling and extinguishing medium. Our system is a closed-loop sprinkler system, designed for early intervention and fire control within the cabinet. The sprinklers automatically activate upon detecting high temperatures, directly cooling the ignition point and adjacent batteries, effectively delaying or stopping the spread of thermal runaway. Simultaneously, the cabinet’s excellent sealing and pressure relief design manages vapor pressure. The primary goal is to contain the fire within the cabinet and prevent catastrophic spread.

Q: What battery sizes are suitable for the storage cabinet?

A: Guheng Energy offers a variety of fixed storage cabinets to accommodate products ranging from single battery modules to complete passenger vehicle battery packs (PACKs). When selecting a model, please provide the specific dimensions, weight, and type (e.g., ternary lithium, lithium iron phosphate) of the batteries you need to store, and our technical team will recommend the most suitable model for you.

Q: What conditions are required to install this type of fixed storage cabinet?

A: There are three main points to consider: site load-bearing capacity (the cabinet and fully loaded batteries are quite heavy), water supply connection (to reserve an interface for the closed sprinkler system), and power supply connection (to power the alarm and monitoring system). We provide detailed installation preparation guidance and can assist with site assessment.