With the rapid development of the new energy vehicle and energy storage industries, the safety and performance of battery packs have become a focal point for the industry. Battery pack airtightness testing equipment, as a critical tool for ensuring battery pack quality, has seen technological innovations that not only improve testing efficiency and accuracy but also have a profound impact on the entire new energy industry. This article will delve into the current state of battery pack airtightness testing equipment, the rise of domestic equipment, its application value, and future development trends, while highlighting the professional contributions of Hangzhou Guheng Energy Technology Co., Ltd. in this field.

Current State and Development Trends of Battery Pack Airtightness Testing Equipment

Analysis of Core Technologies in Current Airtightness Testing Equipment

The core of battery pack airtightness testing equipment lies in using high-precision sensors and automated systems to detect micro-leaks in battery pack casings, ensuring their sealing performance meets stringent industry standards. The current mainstream technologies include:

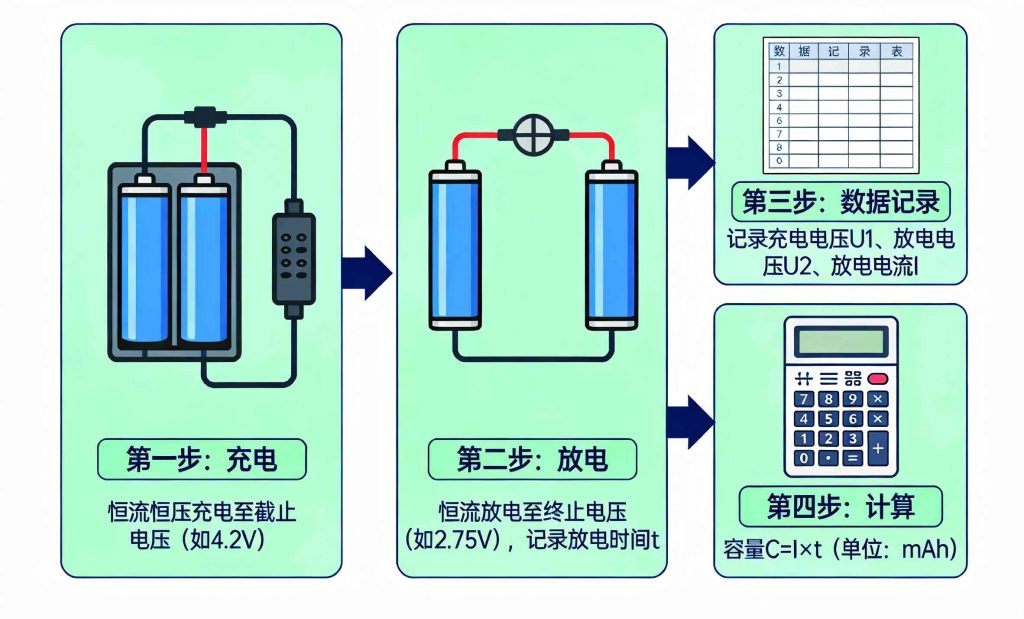

- Differential Pressure Testing Technology: By measuring the pressure difference between the inside and outside of the battery pack, it quickly determines whether a leak exists, suitable for high-efficiency production scenarios.

- Helium Testing Technology: Utilizing helium’s permeability, it detects micro-leaks with extremely high accuracy, widely used in high-end battery pack production.

- Automatic Pressure Regulation Technology: The equipment can automatically adjust testing pressure based on different battery pack specifications, improving compatibility and testing efficiency.

These technologies, combined with advanced algorithms and intelligent control systems, make the testing process more precise and rapid. For example, the Portable Airtightness Leak Testing Instrument LQM-SL2 adopts differential pressure testing and automatic pressure regulation technology, significantly enhancing testing efficiency.

Impact of Technological Upgrades on the New Energy Industry

Technological upgrades have brought multifaceted positive impacts to the new energy industry:

- Improved Production Efficiency: Automated testing equipment reduces human intervention, shortens testing cycles, and meets the demands of large-scale production.

- Enhanced Product Safety: High-precision testing effectively identifies potential leak risks, improving the safety and reliability of battery packs.

- Reduced Production Costs: Intelligent equipment lowers false detection rates and rework rates, optimizing production processes.

These improvements drive new energy vehicles and energy storage equipment toward higher safety standards and lower costs.

The Rise of Domestic Battery Pack Airtightness Testing Equipment

Competitive Advantages of Domestic Brands in the Market

In recent years, domestic brands in the field of battery pack airtightness testing equipment have risen rapidly, demonstrating the following competitive advantages:

- Cost Advantage: Compared to imported equipment, domestic brands offer more competitive pricing, reducing procurement costs for enterprises.

- Localized Services: Domestic brands provide rapid-response after-sales services and technical support, meeting customized customer needs.

- Technological Innovation: Domestic companies have made continuous breakthroughs in core technologies, with some products performing on par with international brands.

For instance, Guheng Energy’s Portable Air-tightness Leak Test Instrument QMM-AK1-1 has gained widespread market recognition for its high cost-performance ratio and stable performance.

How Technological Innovation Helps Domestic Brands Break Through

Domestic brands have achieved market breakthroughs through technological innovation:

- Independent R&D of Core Technologies: Domestic companies have increased R&D investments, developing testing equipment with proprietary intellectual property.

- Intelligent Upgrades: Integration of AI algorithms and IoT technology enables remote monitoring and data analysis for equipment.

- Customized Solutions: Tailored equipment configurations and solutions meet domestic market demands.

These efforts have allowed domestic brands to gradually secure a place in the global market, contributing to the high-quality development of China’s new energy industry.

Application Value of Airtightness Testing Equipment in the New Energy Industry

Critical Role in the Electric Vehicle Sector

In the electric vehicle sector, battery pack airtightness directly impacts vehicle safety and lifespan. Airtightness testing equipment plays a key role in the following areas:

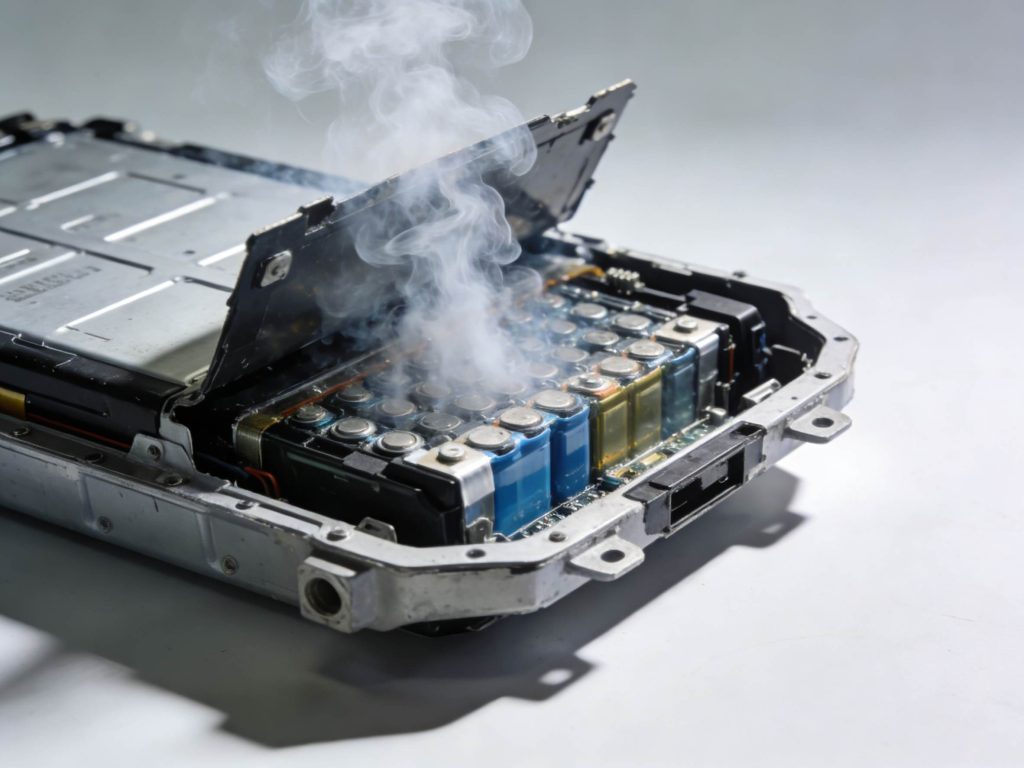

- Preventing Electrolyte Leakage: Ensuring battery pack sealing prevents electrolyte leaks that could cause short circuits or fires.

- Resisting External Environmental Factors: Good airtightness protects batteries from moisture, dust, and other external elements.

- Enhancing Production Consistency: High-precision testing ensures stable quality for every battery pack, meeting the stringent requirements of automakers.

Guheng Energy’s Portable Air-tightness Leak Test Instrument QMP-ZK1-1 is designed specifically for electric vehicle battery packs, offering efficient and precise testing solutions.

Contributions to Battery Safety and Performance Enhancement

Airtightness testing equipment ensures battery pack sealing, providing significant support for battery safety and performance:

| Contribution Area | Specific Impact |

| Safety | Prevents leaks that could cause short circuits, overheating, or explosion risks |

| Lifespan | Protects internal battery structures, extending battery lifespan |

| Performance Stability | Ensures stable output performance in extreme environments |

These contributions directly enhance the market competitiveness of new energy vehicles, boosting consumer confidence in electric vehicles.

Profound Impact of Technological Innovation on Future Industry Development

New Technology Trends and Potential Transformations

In the future, battery pack airtightness testing equipment will see the following technological trends:

- Non-Contact Testing Technology: Using laser or ultrasonic methods for non-destructive testing, improving efficiency and accuracy.

- Big Data and AI Integration: Leveraging data analytics to predict equipment failures and optimize testing processes.

- Green Manufacturing: Developing low-energy testing equipment to align with sustainable development goals.

These new technologies are expected to fundamentally transform the testing industry, driving the new energy sector toward intelligence and sustainability.

Potential Impact on Upstream and Downstream Enterprises in the Supply Chain

Technological innovation not only affects testing equipment manufacturers but also has a profound impact on upstream and downstream enterprises in the supply chain:

- Upstream Enterprises: Suppliers of sensors, chips, and other components need to develop higher-precision products to match new testing equipment.

- Downstream Enterprises: Battery manufacturers and automakers benefit from more efficient testing equipment, reducing production costs and improving product quality.

- Service Providers: Technical service providers must offer more specialized maintenance and upgrade services to meet the needs of intelligent equipment.

These changes will foster collaborative development across the entire new energy supply chain.

Guheng Energy: A Reliable Expert in New Energy Service Technology Solutions

Guheng Energy’s Professional Capabilities in Airtightness Testing

Hangzhou Guheng Energy Technology Co., Ltd., established in 2012 and based in Hangzhou, Zhejiang Province, is a national high-tech and specialized enterprise. The company focuses on service technology development in the new energy sector, particularly in battery pack airtightness testing equipment, boasting multiple core technological advantages:

- Rich Technical Expertise: Over a decade of development, Guheng Energy has created several industry-first products, such as the Battery Pack Service Terminal Final Inspection Instrument (EOS-TEST) and the Portable Air-tightness Leak Test Instrument QMM-AK1-2.

- Patents and Certifications: The company holds over 30 patents (including 6 invention patents), 28 software copyrights, and multiple CE certifications, demonstrating strong technical prowess.

- Industry Influence: Actively participates in industry technical seminars and standard-setting, promoting the standardization of airtightness testing technology.

Core Advantages in Providing Efficient and Precise Solutions

Guheng Energy leverages the following advantages to provide efficient and precise airtightness testing solutions:

- Stringent Quality Management System: Certified under ISO9001, all products undergo rigorous quality inspections and aging tests to ensure stable performance.

- Rapid-Response After-Sales Service: Offers 7×24 technical support with a professional team to address customer issues promptly.

- Customization Capabilities: Provides flexible equipment configurations and solutions tailored to diverse production scenarios.

With its professional capabilities and customer-oriented service philosophy, Guheng Energy has become a trusted partner in the new energy industry.

Frequently Asked Questions

Why Is Airtightness Testing Necessary for Battery Packs?

Airtightness testing for battery packs is a critical step in ensuring battery safety and performance. Battery packs contain electrolytes and sensitive electronic components, and inadequate sealing can lead to the following issues:

- Electrolyte Leakage: Leaking electrolytes may cause short circuits, corrosion, or fires, posing serious threats to vehicle safety.

- External Environmental Intrusion: Moisture, dust, or other elements entering the battery pack can accelerate aging and shorten lifespan.

- Performance Instability: Poor sealing may lead to internal pressure imbalances, affecting the battery’s output performance and consistency.

Through airtightness testing, potential leak points can be identified promptly, ensuring stable operation of battery packs in various extreme environments, thus enhancing the safety and reliability of new energy vehicles.

What Are the Advantages of Domestic Brands in Airtightness Testing Equipment?

Domestic brands in battery pack airtightness testing equipment demonstrate significant advantages:

- High Cost-Performance Ratio: Compared to imported equipment, domestic brands offer more competitive pricing, suitable for large-scale procurement by domestic enterprises.

- Localized Support: Provide rapid-response after-sales services and technical support, capable of customized development based on customer needs.

- Technological Innovation: Domestic companies have made breakthroughs in technologies like differential pressure testing and automatic pressure regulation, with some products reaching international advanced levels.

- Market Adaptability: Domestic brands better understand local market demands, offering solutions that align with actual production scenarios.

For example, Guheng Energy’s portable airtightness leak testing instrument series meets the diverse needs of domestic battery manufacturers with high accuracy and stability.

How Does Guheng Energy Ensure the Reliability of Its Solutions?

Guheng Energy ensures the reliability of its airtightness testing solutions through the following measures:

- Stringent Quality Control: Certified under the ISO9001 quality management system, all equipment undergoes multiple rounds of quality inspections, aging tests, and can provide test reports from authoritative institutions.

- Advanced Technological R&D: Holds over 30 patents and 28 software copyrights, with independently controlled core technologies ensuring stable equipment performance.

- Comprehensive After-Sales Service: Provides 7×24 technical support with a professional team to respond quickly to customer needs, minimizing the impact of equipment failures on production.

- Customer Validation: Guheng Energy’s solutions have been widely adopted by numerous well-known domestic battery manufacturers and automakers, earning consistent praise.

Through these measures, Guheng Energy delivers efficient and reliable airtightness testing solutions, supporting the robust development of the new energy industry.