As a core component of new energy vehicles, new energy battery packs have a direct impact on the vehicle’s range and service life. To ensure that battery packs do not leak during use, air-tightness testing has become a crucial quality control step. This article will introduce the basic concepts of air tightness testing and explore Guheng Energy‘s application in new energy battery packs and its air tightness testing process.

Basic Concepts of Air Tightness Testing

What is Air Tightness Testing?

Air tightness testing involves testing the sealing performance of products such as battery packs to ensure they are leak-free under specified conditions. This process typically involves using specialized equipment to fill the product with dry, clean gas and then monitoring pressure changes to determine product compliance.

The Role and Significance of Air Tightness Testing

Air tightness testing is crucial for protecting the components within the battery pack from dust and moisture. Ensuring that the battery pack meets IP67 or IP68 protection standards effectively improves its safety and reliability. This not only extends the battery pack’s service life but also safeguards the overall performance of new energy vehicles.

Common Airtightness Testing Methods

Common methods include the pressure drop method, helium leak test, and foam leak test. The pressure drop method is widely used due to its simplicity and efficiency. During this process, an airtightness leak tester is used to pressurize the product and monitor the pressure change to assess its sealing performance.

Guheng Energy’s Applications in New Energy Battery Packs

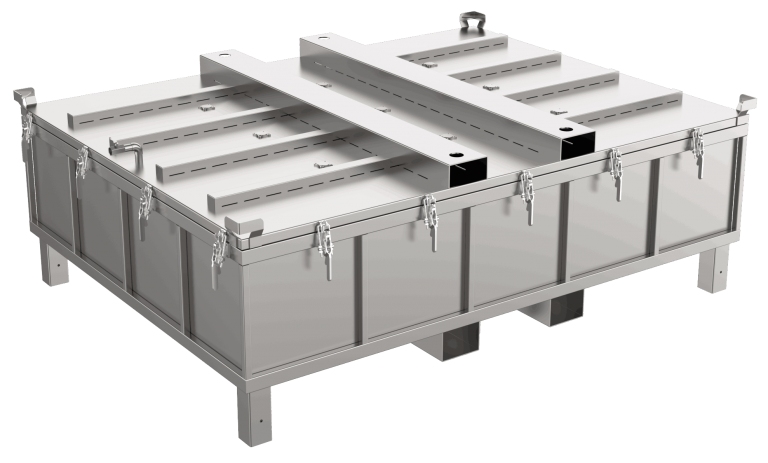

Structural Features of Guheng Energy’s Battery Packs

Guheng Energy’s new energy battery packs are renowned for their superior structural design. These battery packs are composed of multiple modular components, each meticulously crafted to ensure overall structural stability and durability. For example, our explosion-proof transport boxes for hazardous waste power batteries not only provide excellent protection but also boast superior heat dissipation.

Guheng Energy’s Technical Requirements for Airtightness

Guheng Energy strictly adheres to industry standards and maintains stringent control over every production process. The company requires all battery packs to pass airtightness testing to ensure a protection level of IP67 or higher. This requirement applies not only to new products but also to maintenance and upgrade projects, such as complete charge and discharge testers, to ensure that the equipment is always in optimal condition.

The Role of Air Tightness in Guheng Energy’s Product Quality Control

At Guheng Energy, air tightness is considered a key indicator of product quality control. The company is equipped with advanced testing equipment and has established a comprehensive testing process to ensure consistent quality for every product. This rigorous approach not only enhances the company’s reputation but also strengthens customer confidence.

Guheng Energy’s Airtightness Testing Process

Pre-Test Preparation

Before conducting an air tightness test, the equipment must undergo a comprehensive inspection, including cleaning the pipes and calibrating the instrument. Furthermore, it is necessary to confirm that the product under test has no obvious surface defects that could affect the test results.

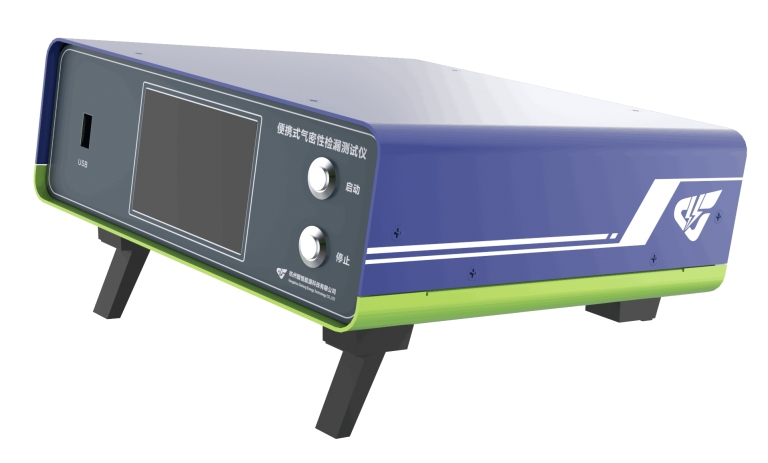

Testing Equipment and Its Principle

Guheng Energy uses an advanced automotive battery health testing solution. This system utilizes high-precision sensors to monitor internal pressure changes. After the system fills the chamber with dry, clean, and impurity-free gas, it maintains the pressure for a period of time before recording data.

Testing Steps

First, place the product under test on a dedicated test platform and connect it to the leak detector. The device then starts according to the programmed program, injecting a standard pressure into the chamber. After a certain period of time, the system automatically records and analyzes the pressure changes. If the pressure drops beyond the set standard, the battery pack is deemed unqualified; otherwise, it is qualified. In summary, we can see how Guheng Energy uses rigorous scientific methods to ensure the quality of its new energy battery packs. In the future, the company will continue to focus on technological innovation to provide users with safer and more reliable product solutions.

Potential Problems Caused by Airtightness

Battery Safety Hazards

Battery packs with unqualified airtightness may pose serious safety hazards. Since the components within the battery pack must operate in a dust-free and moisture-free environment, a failure of the seal allows external dust and moisture to enter, causing short circuits or battery failure. Furthermore, poor airtightness can cause electrolyte leakage, increasing the risk of fire or explosion. Therefore, ensuring the airtightness of the battery pack is crucial during production and use.

Shortened Product Lifespan

Airtightness directly impacts the lifespan of the battery pack. Over time, if the battery pack is continuously exposed to external environmental factors, its performance will gradually deteriorate. Battery packs with poor airtightness are particularly susceptible to damage in adverse weather conditions, such as heavy rain or extreme heat. This not only shortens product lifespan but also impacts overall vehicle performance and user experience.

Rising After-Sales Costs

Once airtightness issues occur, after-sales service costs will increase significantly. Repairing or replacing damaged battery packs requires significant manpower, material, and financial resources. Furthermore, repeated problems can lead to a decline in customer trust in the brand, negatively impacting market reputation. Therefore, preventing problems through rigorous airtightness testing is a key measure to reduce after-sales costs.

Solutions to Improve Airtightness Testing Efficiency

Introduction of Automated Testing Equipment

To improve testing efficiency, Guheng Energy has introduced automated testing equipment. This equipment can complete large-volume product testing in a short period of time and provide high-precision data analysis. For example, the company has adopted an automotive battery health monitoring solution that integrates automated control technology and high-precision sensors, making the entire testing process faster and more accurate. Furthermore, this equipment effectively reduces errors associated with manual operation, improving overall work efficiency.

Data Acquisition and Analysis System Optimization

Guheng Energy is continuously optimizing its data acquisition and analysis system to enhance data processing capabilities within the testing process. By introducing advanced data management software, the company can monitor data changes at each testing stage in real time and quickly identify potential issues. This precise data analysis capability not only helps the company improve product quality but also provides important reference for new product development.

Guheng Energy’s Continuous Improvement Strategy

Guheng Energy consistently adheres to a continuous improvement strategy to continuously enhance product quality and customer satisfaction. The company regularly evaluates its existing testing processes and makes adjustments based on market feedback. For example, through user feedback, the company discovered that a certain battery pack model had insufficient airtightness under specific conditions, and it quickly implemented improvements. This proactive approach to market demand has kept Guheng Energy at the forefront of the industry.

FAQ

Q: Why is airtightness testing so important?

A: Airtightness testing ensures that the battery pack maintains a good seal under various environmental conditions, protecting the internal components from external factors. This is crucial for the safe operation and extended service life of new energy vehicles.

Q: How does Guheng Energy ensure that its products meet IP67 or higher protection levels?

A: Guheng Energy strictly adheres to industry standards and uses advanced automated testing equipment to ensure compliance at every stage of production. The company is also continuously optimizing its data collection and analysis systems to improve overall inspection efficiency and accuracy.

Q: What should be done if an airtightness issue in a battery pack is discovered?

A: If a problem is discovered, immediately stop using the product and contact a professional technician for repair or replacement. During this process, follow the manufacturer’s instructions to ensure safe operation.