Leak detectors are crucial in modern industry, especially in the new energy sector. They accurately detect product sealing performance, effectively preventing gas or liquid leaks and ensuring product quality and safety. When selecting a leak detector, focus on five core performance indicators: detection accuracy, detection efficiency, stability and repeatability, compatibility with applicable operating conditions, and compliance and protection level. This article will provide an in-depth analysis of these five key points and, combined with the characteristics of Guheng Energy products, help you select an efficient model and avoid common pitfalls.

Understanding the Core Role of Leak Detectors

Application Scenarios of Leak Detectors in Industrial Testing

Leak detectors are widely used in various industrial fields, including automotive manufacturing, electronics, and medical devices. In these industries, ensuring product sealing not only affects product lifespan but also directly impacts safety and performance. Especially in the new energy sector, airtightness testing is particularly important for components such as battery packs and liquid cooling plates.

Guheng Energy’s Technical Advantages in Airtightness Testing

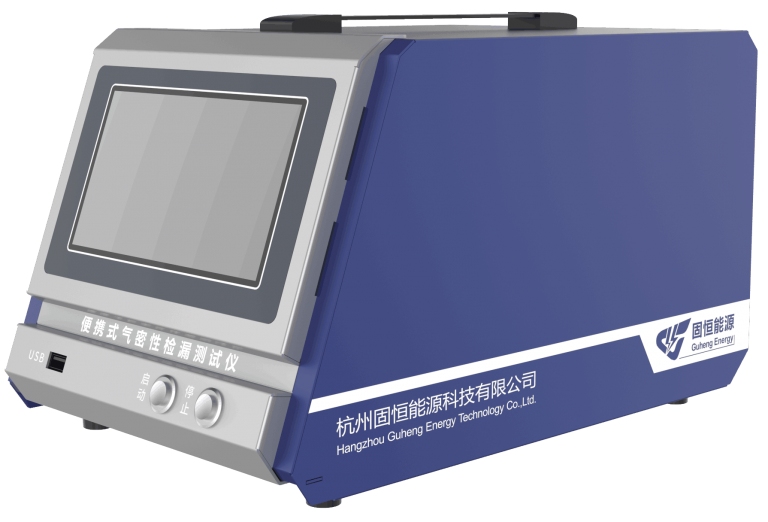

As a company specializing in new energy service technology solutions, Guheng Energy has significant advantages in airtightness testing. Our QMM series portable airtightness leak detectors, such as the QMM-AK1-2 and QMM-ZK1, utilize advanced air pressure control technology to effectively address pressure regulation and stability issues encountered during testing.

Why Understanding Key Performance Indicators is Essential Before Selection

Choosing the right airtightness leak detector requires a clear understanding of its performance indicators. This not only helps you find the best equipment for your needs but also avoids costly or inaccurate testing due to equipment mismatch.

Detection Accuracy: A Key Parameter Determining Micro-Leak Detection

Accuracy Unit Analysis: What Does Pa-Level Resolution Mean?

Detection accuracy is the primary metric for evaluating the performance of an airtightness leak detector. It directly determines the device’s ability to detect micro-leakages and is a key criterion for evaluating the quality of an airtightness leak detector. Resolution, measured in Pascals, represents how minute pressure changes a device can detect. High accuracy means it can detect even the smallest leaks, ensuring product quality.

Guheng Energy Product Accuracy Comparison: How to Meet Different Operating Requirements

- QMM-AK2-1 Portable Leak Tester: Features high-precision testing capabilities, suitable for most industrial scenarios, and offers excellent value for money.

- QMM-ZK1 Series: Maintains excellent accuracy even under complex operating conditions, meeting high-standard testing requirements.

Balancing Accuracy and Cost: Choosing the Most Suitable Model

When selecting equipment, it’s important to strike a balance between accuracy and cost. For general industrial testing, equipment with a resolution of 50 Pa or less is sufficient. For applications requiring high accuracy (such as core components for new energy), we recommend models with a resolution of 10 Pa or less. Not all applications require the highest accuracy, so choosing the right model based on your needs can effectively control costs.

Testing Efficiency: Cycle Speed Affects Production Line Rhythm

How Test Cycle Speed Affects Production Efficiency

Testing efficiency is often measured by “cycle speed,” which is the time required to complete a single test. High-efficiency equipment can significantly shorten production line cycles and avoid production bottlenecks. Fast and accurate testing improves production efficiency, reduces downtime, and thus increases overall productivity.

Guheng Energy’s High-Efficiency Leak Detectors: Introduction and Application Scenarios

Our high-efficiency equipment, such as the QMM-ZK1 series, is designed for high-volume production lines requiring rapid testing. Its short cycle time supports continuous, rapid testing, and its efficient operation ensures smooth production line operation.

How to Match the Appropriate Equipment to the Production Line Rhythm

When selecting equipment, consider its cycle speed based on the actual production line to ensure seamless integration with existing processes and improve overall efficiency. Clarify the existing production line rhythm and test time requirements, and select equipment that matches the cycle speed. For high-variety, low-volume production, portable models with convenient operation and quick setup are preferred.

Stability and Repeatability: Ensuring Reliability in Every Test

Repeatability Definition and Its Significance in Practical Applications

Repeatability refers to the consistency of a device’s measurements under the same conditions over multiple times. This metric is crucial because it directly impacts the reliability and consistency of the results.

Guheng Energy Product Stability Testing Standards Analysis

Guheng Energy conducts stability testing in strict accordance with international standards to ensure the long-term reliability of each device. For example, we perform multiple pressure cycling tests and long-term continuous operation tests on models such as the QMM-AK1-2 to ensure their long-term stability. They demonstrate excellent stability under harsh operating conditions and are suitable for high-intensity use.

How to Determine the Long-Term Performance Stability of a Device

By reviewing the manufacturer’s testing standards and user feedback (especially long-term user reviews), you can initially determine whether the device can maintain stable performance over the long term.

Applicable Condition Matching: A Guide to Selecting Differential Pressure, Direct Pressure, and Flow Methods

Principles and Applications of Three Common Testing Methods

Differential pressure, direct pressure, and flow methods are three common testing methods, each with its own application scope.

- Differential pressure method:Suitable for detecting small leaks, with high accuracy, and commonly used in batteries, precision components, etc. 2. Direct Pressure Method:Suitable for workpieces with simple structures and small internal volumes, offering fast inspection speed.

- Flow Method: Suitable for larger leaks or when quantitative leak flow measurement is required.

Guheng Energy’s Application Scenario List of Various Models

We provide a detailed list to help customers select the appropriate model. For example, the QMM-ZK1 series is suitable for complex structural parts, while the QMM-AK2-1 is more suitable for simple structural parts.

| Product Model | Recommended

Inspection Method |

Applicable Scenario |

| QMM-ZK1 Series | Differential Pressure Method | Complex structural parts, new energy components |

| QMM-ZK1 Series | Direct Pressure/Differential Pressure Dual Model | A variety of simple and complex work pieces |

How to Select an Inspection Method Based on the Characteristics of the Product Under Test

Based on understanding the characteristics of the product under test, such as analyzing the workpiece structure, internal volume, and leakage standards, you can combine the characteristics of different methods or select equipment that supports multi-mode inspection to meet diverse inspection needs.

Compliance and Protection Rating: Ensuring Equipment Durability and Safe Operation

Compliance refers to a product’s compliance with industry and international standards, while the IP rating (IP rating) indicates the device’s dust and water resistance. Together, these two ensure the device’s safety and durability in diverse environments. When selecting a device, choose the appropriate device based on the actual operating environment.

The Meaning of IP Ratings

For example, IP54 indicates a dustproof rating of 5 (good dustproof) and a waterproof rating of 4 (splashproof), making it suitable for most industrial environments. For dusty and humid environments, a higher IP rating (such as IP65) is recommended.

Guheng Energy Product Compliance and Protection Performance

Relevant regulatory certifications not only indicate high-quality products but also facilitate a smoother purchasing process. Therefore, when purchasing, consider whether the manufacturer possesses these certifications. Guheng Energy’s products are all certified and compliant with industry standards. Our products undergo rigorous testing and demonstrate excellent dust and water resistance, ensuring safe operation in a variety of environments. The device’s robust housing design and IP rating of IP54 or higher adapt to diverse operating conditions.

Purchasing Recommendations

Confirm that the device has the necessary certifications (such as CE, ISO, etc.). Choose an IP rating that matches your actual operating environment (such as workshop cleanliness and humidity).

How to choose the best leak detector for you?

When selecting a leak detector, systematically consider the five key points above and combine them with your specific needs: Clarify your testing requirements: including accuracy, efficiency, and applicable methods. Evaluate your budget: Find a balance between accuracy, functionality, and cost. Confirm environmental requirements: Select equipment with the appropriate IP rating based on the operating conditions. Select a reliable supplier: Prioritize brands with strong technical expertise, comprehensive service, and a strong reputation.

Guheng Energy, leveraging its deep technical expertise and extensive industry experience, offers a variety of airtightness leak detection solutions, covering various accuracy and efficiency requirements, and supporting customized services. For more product details or professional selection advice, please contact our technical team.

FAQ

Q: Why is the accuracy of an airtightness leak detector so important?

A: Detection accuracy directly determines the device’s ability to detect minute leaks. For example, a leak detector with Pa-level resolution can capture extremely subtle pressure changes, which is crucial for the safety and performance of core new energy components such as battery packs and liquid cooling plates. Choosing equipment with the appropriate accuracy ensures quality while avoiding over investment.

Q: How do I choose the right leak detector for my production line?

A: First, consider the production line’s cycle speed. For high-volume production, a high-efficiency device (such as the QMM-ZK1 series) is needed to shorten testing time. For small batches of multiple products, a portable model with flexible settings (such as the QMM-AK2-1) is recommended. Ensuring that the device’s testing efficiency matches the production line’s pace can effectively improve overall productivity.

Q: What are the differences between differential pressure, direct pressure, and flow methods, and how should I choose?

A: The differential pressure method is suitable for detecting small leaks and is commonly used in batteries and precision components. The direct pressure method is fast and suitable for simple, small workpieces. The flow method is suitable for quantitative analysis of leaks or for larger leaks. If your work conditions are diverse, it’s recommended to choose a model that supports multiple testing methods, such as the QMM-AK2-1.

Q: What compliances and protection levels should I consider when purchasing a leak detector?

A: You need to confirm that the device complies with relevant international standards (such as CE and ISO) and select a protection level based on your specific environment. For example, IP54 is sufficient for general operating conditions. For environments with severe dust or humidity, IP65 or higher is recommended. This ensures the equipment remains reliable and safe over the long term.

Q: How do you balance detection accuracy and cost?

A: Not all applications require the highest accuracy. For general industrial detection, a resolution of 50Pa or less is sufficient. For core new energy components, a resolution of 10Pa or less is recommended. Choosing the right model based on actual needs can effectively control your budget while ensuring detection results.