As core components of electric vehicles and energy storage systems, air tightness testing of new energy battery packs is crucial. Air tightness not only affects the performance of the battery pack but also directly impacts its safety and service life. Effective air tightness testing ensures reliable operation of the battery pack in various environments and avoids potential leakage risks.

The Importance of Air Tightness Testing

Why Do New Energy Battery Packs Need Air Tightness Testing?

New energy battery packs require air tightness testing primarily because they contain numerous precision components that are highly sensitive to the external environment. Particularly in humid and dusty conditions, a poorly sealed battery pack can lead to internal short circuits, corrosion, and other problems. Furthermore, a battery pack with good air tightness can better maintain stable internal pressure, improving overall performance.

Possible Problems Caused by Poor Air Tightness

If a new energy battery pack does not meet air tightness standards, a series of problems may arise. For example, moisture entering the battery pack can cause short circuits or corrosion; dust intrusion can affect contact conductivity, increase internal resistance, and reduce efficiency. Furthermore, gas leakage can cause environmental pollution and safety hazards. Therefore, ensuring the airtightness of battery packs is essential for their proper operation.

Commonly Used Airtightness Testing Technologies of Guheng Energy

Guheng Energy has extensive experience in the new energy sector and offers a variety of advanced airtightness testing technologies to meet the needs of different battery pack types.

Differential Pressure Method

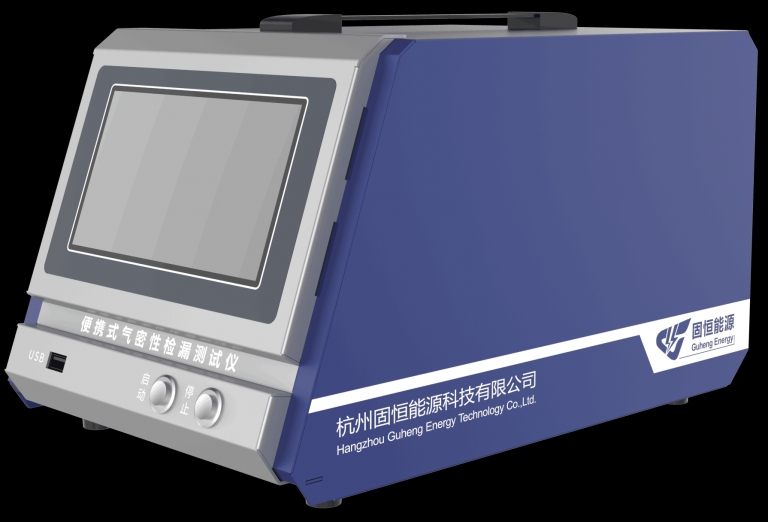

The differential pressure method is a common and effective airtightness testing technique. By applying different pressures inside and outside the battery pack and measuring the pressure difference, leaks can be determined. This method is suitable for most standard battery packs. The QMM-AK1–2 portable airtightness leak tester provided by Guheng Energy utilizes this technology, offering high accuracy and ease of operation.

Flow Method

The flow method assesses the airtightness of a product by measuring the mass flow rate of leaking material per unit time. This method is suitable for testing complex structures or large components. Guheng Energy also has specialized equipment in this field to meet diverse customer needs.

Applicable Scenarios and Pros and Cons of Various Testing Methods

Applicable Battery Pack Types of Different Methods

Each testing method has its specific application scenarios. For example, the differential pressure method is suitable for most standard battery packs, while the flow method can be used for complex structural components.

Testing Accuracy, Efficiency, and Cost Comparison

For general businesses, choosing the appropriate method based on specific needs can achieve optimal results. In short, the development of the new energy industry is inseparable from strict control of key components such as new energy battery packs. The adoption of advanced air tightness testing technology not only improves product quality but also ensures user safety. Guheng Energy, with its professional equipment, such as the QMM-AK2-1 portable air tightness leak tester, provides strong support to the industry, making the application of new energy more widespread, safer, and more reliable.

Guheng Energy‘s Technological Advantages in Air Tightness Testing Equipment

Guheng Energy has demonstrated significant technological advantages in the field of air tightness testing. Leveraging its independently developed core equipment technology, Guheng Energy is able to provide efficient and accurate testing services for new energy battery packs.

Independently Developed Core Equipment Technology

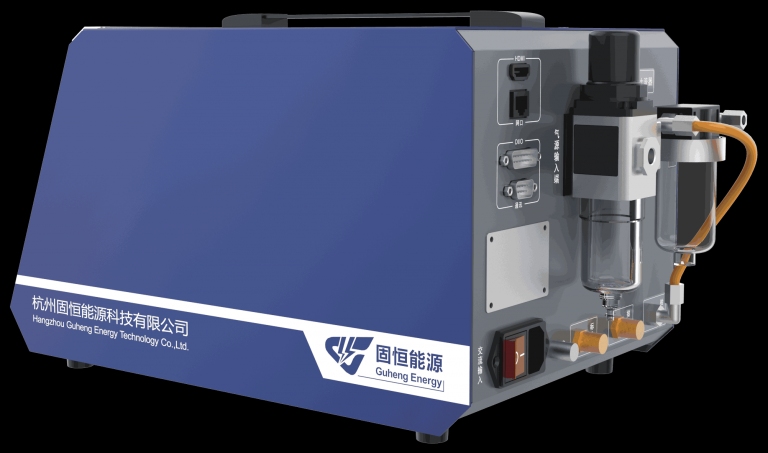

Guheng Energy is dedicated to independently developing high-performance airtightness testing equipment. These devices utilize advanced air pressure control technology, automatically adjusting the test pressure to ensure stability and accuracy during testing. For example, the QMM-AK2-1 portable airtightness leak tester is a product specifically developed for the new energy sector. It not only features imported key components but also a high-definition Android screen for simplified operation. Furthermore, its compact size and portability make it ideal for on-site testing.

Intelligent Control System and Data Management

Guheng Energy’s testing equipment is equipped with an intelligent control system that automatically records and analyzes test data. This data can be monitored in real time and tracked and managed long-term via cloud storage. The intelligent data management system allows users to easily review historical test records, identifying potential problems promptly and taking effective preventative measures. This intelligent design significantly improves work efficiency and provides greater user convenience.

Applied to Various New Energy Battery Pack Product Lines

Guheng Energy’s airtightness testing technology can be widely applied to various new energy battery pack product lines, including liquid cold plates, PDUs, PEUs, EDSs, and battery boxes. Its diverse product solutions can meet the personalized needs of different customers. For example, the QMM-AK2-1 portable air leak tester is designed for applications requiring high precision and is ideal for testing complex structures or large components. These devices not only improve testing accuracy but also reduce operating costs.

Air leak testing process and precautions

To ensure accurate and reliable air leak test results for new energy battery packs, it is necessary to strictly follow certain procedures and pay attention to certain key points.

Pretest preparation

Before conducting an air leak test, thorough preparation is required. First, ensure that the surface of the battery pack to be tested is clean, free of visible dirt and moisture, which can affect the test results. Second, select the appropriate model and parameter settings of testing equipment, such as the QMM-AK2-1 portable air leak tester, to ensure that the test conditions match the actual operating environment. Furthermore, it is necessary to check the normal operation of the equipment, including the connection pipes and sensor sensitivity, to avoid misdiagnosis due to equipment malfunction.

Critical Control Points During the Testing Process

In actual operation, several critical control points require special attention. First, during the pressure equilibration phase, ensure that the gas is dry, clean, and free of impurities and maintained for a period of time to achieve pressure equilibrium. Second, during the measurement process, pay attention to changes in internal pressure. If the pressure drops beyond the set standard value, further investigation is required. Furthermore, for different battery pack types, parameters should be adjusted according to their characteristics to achieve optimal results.

Common Operational Mistakes and Solutions

During the airtightness testing process, some common mistakes can lead to erroneous results. For example, using the same parameter settings for different battery pack types can result in inaccurate results. Therefore, before beginning the test, carefully read the equipment manual and adjust the parameters according to the specific situation. Furthermore, for novice operators, lack of experience can lead to operational errors, so professional training is recommended to improve operational skills. If you encounter complex problems that cannot be resolved, please feel free to contact the Guheng Energy technical support team for professional guidance and assistance.

FAQ

Q: Why choose Guheng Energy as your partner?

A: Guheng Energy has extensive experience and leading technology. Its independently developed high-performance airtightness testing equipment, such as the QMM-AK1-2 Portable Airtightness Leak Tester and the QMM-AK2-1 Portable Airtightness Leak Tester, provides customers with accurate and reliable data. Furthermore, its intelligent management system allows users to easily track historical records, improving work efficiency.

Q: How do I determine whether a battery pack requires airtightness testing?

A: Generally speaking, airtightness testing is required for both newly manufactured and repaired battery packs. Furthermore, if any abnormalities are detected during use, such as performance degradation or safety hazards, prompt inspection should be performed to eliminate potential risks.

Q: What after-sales services does Guheng Energy provide?

A: Guheng Energy offers comprehensive after-sales services, including equipment installation and commissioning, operator training, and technical support. If you have any questions or inquiries, please feel free to contact our after-sales team. We will be happy to assist you.