With the rapid development of the new energy industry, the sealing performance of core components such as battery packs, motors, and controllers directly impacts product safety and reliability. Gas tightness leak detectors, as critical testing equipment in the new energy sector, have become the preferred choice for many companies to ensure product quality due to their high precision, efficiency, and intelligent features. This article will explore the unique features, technical advantages, and application scenarios of gas tightness leak detectors in the new energy sector, as well as guide you on selecting the right equipment to enhance production efficiency.

The Importance of Gas Tightness Leak Detectors in the New Energy Sector

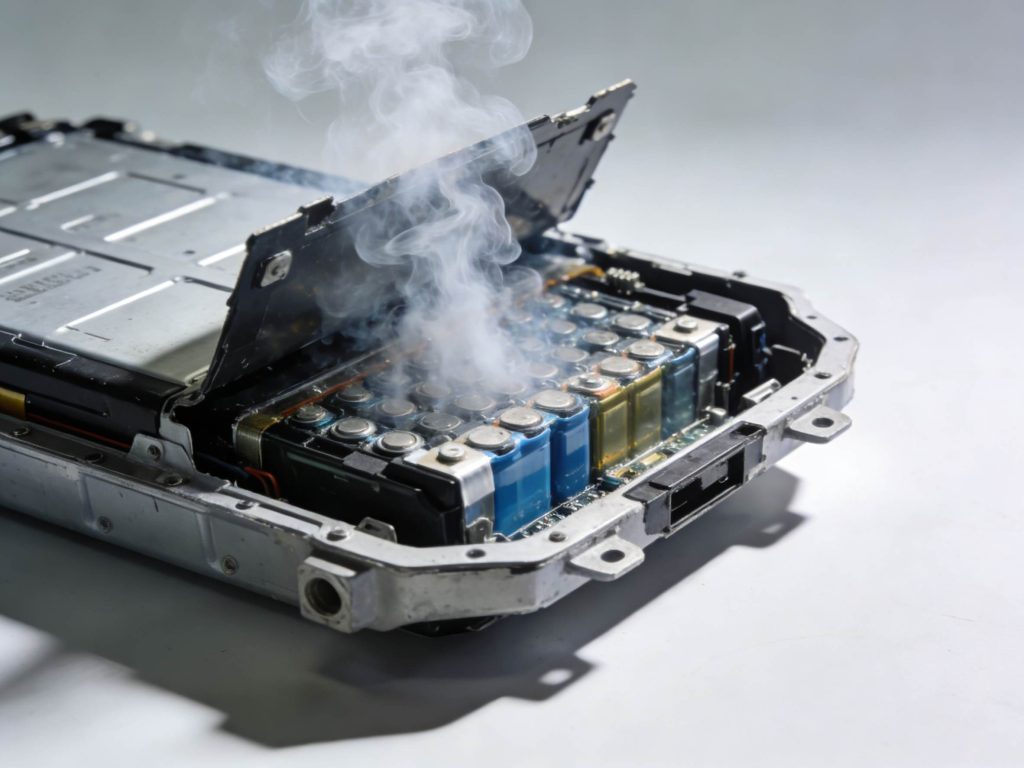

In the new energy industry, particularly in electric vehicles and energy storage systems, the sealing requirements for components are exceptionally high. For instance, a minor leak in a battery pack could lead to electrolyte leakage, short circuits, or even fires. Therefore, gas tightness leak detectors play an indispensable role in production and testing processes. They ensure stable operation under extreme conditions by accurately detecting the sealing performance of components.

Gas tightness leak detectors are not only used for battery packs but are also widely applied in testing motor housings, connectors, cooling systems, and more. Below is a summary of their core value in the new energy sector:

- Enhanced Safety: Ensures no leaks, reducing safety risks caused by sealing failures.

- Quality Assurance: High-precision testing reduces defect rates and improves product consistency.

- Increased Efficiency: Automated testing processes shorten test times, meeting large-scale production needs.

Core Features of Gas Tightness Leak Detectors

The widespread use of gas tightness leak detectors in the new energy sector is attributed to their unique technical features. Below is a detailed analysis of their main advantages:

1. High-Precision Detection Capability

New energy components often have complex structures and tiny sealing points, making traditional testing methods insufficient. Modern gas tightness leak detectors employ advanced differential pressure, helium, or vacuum detection technologies to identify leaks as small as micrometers. For example, the Portable Air-tightness Leak Test Instrument LQM-SL2 achieves a detection accuracy of 0.1Pa, ideal for high-demand battery pack testing.

| Detection Technology | Accuracy Range | Applicable Scenarios |

| Differential Pressure | 0.1-10 Pa | Battery Packs, Motor Housings |

| Helium Detection | 0.01-1 Pa | High-Precision Lab Testing |

| Vacuum Detection | 0.1-5 Pa | Cooling Systems, Connectors |

2. Intelligent and Automated Operation

With the advancement of Industry 4.0, gas tightness leak detectors integrate intelligent control systems, supporting automated operations and real-time data monitoring. For instance, the Portable Air-Tightness Leak Test Instrument QMM-AK1-1 features a touchscreen interface and automatic pressure regulation, adjusting test parameters based on different workpieces to minimize manual intervention and improve efficiency.

Intelligent features include:

- Automatic Calibration: Equipment can self-calibrate periodically to maintain long-term accuracy.

- Data Recording and Traceability: Supports storage and export of test data for quality management.

- Remote Monitoring: Some high-end models support cloud connectivity for real-time production data management.

3. Portability and Flexibility

New energy production scenarios vary, requiring equipment to adapt to different environments. Portable gas tightness leak detectors have become increasingly popular due to their lightweight design and flexible operation. For example, the Portable Air-tightness Leak Test Instrument QMM-AK1-2 is lightweight and easy to carry, suitable for both on-site and laboratory testing.

Portability advantages:

- Compact Design: Easy to operate in confined spaces.

- Multi-Scenario Compatibility: Supports production lines, repair stations, and R&D labs.

- Quick Deployment: Plug-and-play with no complex setup required.

4. High Testing Speed

In large-scale new energy production, testing speed directly impacts line efficiency. Gas tightness leak detectors, with optimized testing processes, can complete a full test in seconds. For instance, the LQM-SL2 model has a test cycle of just 3-5 seconds, meeting high-throughput production demands.

5. Eco-Friendly and Energy-Saving Design

The new energy industry emphasizes sustainability, and gas tightness leak detectors reflect this in their design. They use low-power components, and some models support recyclable gas (e.g., helium) reuse, reducing operational costs and environmental impact.

Application Scenarios of Gas Tightness Leak Detectors in the New Energy Sector

Gas tightness leak detectors are used across all stages, from R&D to mass production, in the new energy industry. Below are some typical scenarios:

1. Battery Pack Production

Battery packs are core components of electric vehicles and energy storage systems, with sealing performance directly affecting safety and lifespan. Gas tightness leak detectors test battery pack housings, seals, and connection ports to ensure no electrolyte leakage risks.

2. Motor and Controller Testing

Motor and controller housings must withstand high temperatures and humidity. Gas tightness leak detectors verify their sealing performance to prevent water or dust ingress that could cause failures.

3. Cooling System Testing

Cooling systems in new energy vehicles must be leak-free to maintain efficient heat dissipation. Portable gas tightness leak detectors quickly test pipelines and interfaces for sealing integrity.

4. R&D and Quality Validation

During product development, gas tightness leak detectors validate the sealing performance of new designs, helping engineers optimize structures and material choices.

How to Choose the Right Gas Tightness Leak Detector?

When selecting a gas tightness leak detector, consider the following factors:

| Selection Factor | Recommendation |

| Detection Accuracy | Choose the appropriate accuracy range (e.g., 0.1Pa or higher) based on workpiece requirements. |

| Testing Speed | High-throughput lines require equipment with short test cycles. |

| Portability | Prioritize lightweight models for on-site testing. |

| Intelligence Level | Opt for models with data traceability and remote monitoring for efficiency. |

| After-Sales Service | Choose brands with robust support, like Guheng Energy. |

We recommend consulting professional suppliers based on your specific needs. Guheng Energy offers free technical consultations and equipment selection services—visit the official homepage for more details.

Guheng Energy: Your Trusted New Energy Service Technology Solution Expert

Guheng Energy is a technology leader in the new energy sector, dedicated to providing high-quality gas tightness testing and battery maintenance solutions. Since its establishment, Guheng has leveraged over a decade of technical expertise and innovation to develop industry-first products, including the Battery Pack Service Terminal Tester (EOS-TEST), battery balancing maintenance equipment, and gas tightness leak detectors. The company holds over 30 patents (including 6 invention patents) and 28 software copyrights, with products certified by CE, earning international recognition for quality.

Guheng Energy is ISO9001-certified, adhering to international standards for R&D, production, and sales. All products undergo rigorous quality inspections and aging tests, with reports available from authoritative testing agencies. Additionally, the company offers rapid-response after-sales service and collaborates with insurers to provide a worry-free user experience. Guheng actively participates in industry associations’ technical discussions and standard-setting, contributing to the sustainable development of the new energy sector.

Choosing Guheng Energy, you gain:

- Professional Technical Support: Customized solutions from an experienced technical team.

- Highly Reliable Products: Multi-stage quality validation ensures long-term stability.

- Full Lifecycle Service: Comprehensive support from equipment selection to after-sales maintenance.

Frequently Asked Questions

1. How Is the Detection Accuracy of Gas Tightness Leak Detectors Ensured?

The detection accuracy of gas tightness leak detectors relies on their core sensors and calibration systems. Guheng Energy’s detectors use high-precision differential pressure sensors paired with automatic calibration to keep errors within 0.1Pa. Additionally, equipment undergoes rigorous factory aging tests and third-party validation to ensure long-term stability. Users should regularly calibrate the equipment and maintain stable temperature and humidity in the testing environment to further enhance accuracy.

2. Which Scenarios Are Portable Gas Tightness Leak Detectors Suitable For?

Portable gas tightness leak detectors are ideal for their lightweight and flexible design in scenarios such as: 1) On-site repairs, like battery pack testing at electric vehicle service stations; 2) Small-batch production, suitable for SMEs’ production lines; 3) R&D labs for validating new product sealing performance. For example, Guheng Energy’s QMM-AK1-2 model weighs only 5kg and supports rapid deployment, making it perfect for mobile testing needs.

3. Are Maintenance Costs for Gas Tightness Leak Detectors High?

Maintenance costs for gas tightness leak detectors are generally low, especially for Guheng Energy’s equipment. The modular design allows easy replacement of key components (e.g., sensors and gas circuits), reducing repair complexity. Guheng offers a one-year free warranty and rapid-response technical support, and regular maintenance (e.g., cleaning gas circuits, replacing filters) can extend equipment lifespan. For helium-based models, gas recycling systems are recommended to lower operational costs.