With the rapid development of the new energy industry, batteries, as the core components for energy storage and power supply, directly impact the efficiency and lifespan of equipment. Battery capacity testing is a critical process in evaluating battery performance. This article will provide a detailed explanation of the principles of battery capacity testing, the operational steps, precautions, and how to ensure the accuracy of test results through scientific methods, helping businesses and individuals better manage their battery assets.

Principles of Battery Capacity Testing

1. Definition of Battery Capacity

Battery capacity refers to the amount of electric charge a battery can store and release under specific conditions, typically measured in ampere-hours (Ah) or milliampere-hours (mAh). Capacity reflects the battery’s energy storage capability and is one of the core indicators for evaluating battery performance.

2. Testing Principle

The principle of battery capacity testing is based on the law of charge conservation. It involves measuring the amount of charge released by a battery under specific discharge conditions to calculate its capacity. Typically, the constant current discharge method is used, where the battery is discharged at a constant current until the voltage drops to a cutoff voltage. The capacity is then calculated based on the discharge time and current. The formula is as follows:

Capacity (Ah) = Discharge Current (A) × Discharge Time (h)

For example, if a battery is discharged at a constant current of 1A for 10 hours, its capacity is 10Ah.

3. Factors Affecting Test Results

Battery capacity test results are influenced by several factors, including:

- Discharge Rate: Higher discharge currents can lead to reduced capacity (Peukert’s effect).

- Ambient Temperature: High temperatures may increase capacity but damage battery lifespan, while low temperatures reduce capacity.

- Battery Aging: As the number of charge-discharge cycles increases, battery capacity gradually declines.

- Test Equipment Accuracy: The resolution and calibration of the equipment directly affect the reliability of the results.

How to Accurately Conduct Battery Capacity Testing

To ensure the accuracy of battery capacity testing, it is essential to follow a scientific process and use professional equipment. Below are the detailed steps and precautions.

1. Pre-Test Preparations

Before conducting a battery capacity test, the following preparations are necessary:

- Check Battery Condition: Ensure the battery has no physical damage or leakage and that its voltage is within the normal range.

- Calibrate Test Equipment: Use high-precision testing instruments, such as GuHeng Energy’s Battery Pack Service Terminal Tester, and ensure the equipment is calibrated.

- Set Test Environment: Control the test environment temperature between 20-25°C to avoid extreme temperatures affecting results.

- Determine Discharge Parameters: Select appropriate discharge current and cutoff voltage based on the battery’s specifications, typically found in the battery’s technical manual.

2. Testing Steps

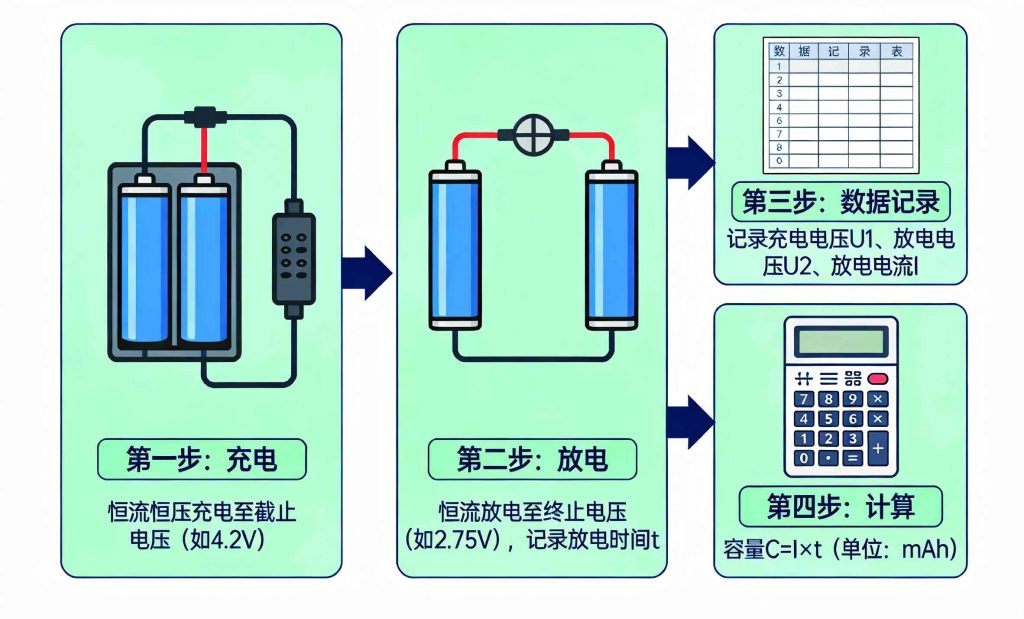

The following is the standard procedure for battery capacity testing:

- Fully Charge: Use a standard charger to charge the battery to 100% and let it rest for 1-2 hours to stabilize the voltage.

- Connect Test Equipment: Properly connect the battery to the testing instrument, ensuring good contact to avoid contact resistance affecting results.

- Set Discharge Parameters: Input the constant discharge current and cutoff voltage on the test equipment. For example, for lithium batteries, the cutoff voltage is typically 2.8V-3.0V.

- Start Discharge: Activate the test equipment and record the voltage, current, and time during the discharge process.

- Data Analysis: After the discharge is complete, the equipment will automatically calculate the capacity and generate a test report. Verify if the data meets expectations.

3. Data Recording and Analysis

After the test, record the following key data:

- Discharge current

- Discharge time

- Cutoff voltage

- Calculated capacity

It is recommended to compare the test results with the battery’s nominal capacity to assess its health. If the capacity is below 80% of the nominal capacity, maintenance or replacement may be required. GuHeng Energy’s Portable Single-Cell Battery Maintenance Instrument can help users quickly diagnose battery conditions.

4. Precautions

To ensure accurate test results, pay attention to the following:

- Avoid Over-Discharge: Over-discharging can cause irreversible damage to the battery.

- Regular Equipment Calibration: The accuracy of the test equipment directly impacts result reliability.

- Repeat Testing: To eliminate random errors, conduct 2-3 tests and take the average value.

- Safe Operation: Wear protective gear during testing to prevent short circuits or battery overheating.

Applications of Battery Capacity Testing

Battery capacity testing is widely used in the following fields:

- New Energy Vehicles: Assessing the health of power batteries to ensure vehicle range.

- Energy Storage Systems: Detecting capacity degradation in storage batteries to optimize system efficiency.

- Consumer Electronics: Testing battery performance in devices like mobile phones and laptops.

- Industrial Equipment: Ensuring the reliability of backup power batteries.

| Application Scenario | Testing Requirements | Recommended Equipment |

| New Energy Vehicles | High precision, batch testing | Battery Pack Service Terminal Tester |

| Energy Storage Systems | Long-cycle testing, data analysis | Battery Pack Balancing Maintenance Instrument |

| Consumer Electronics | Portable, rapid testing | Portable Single-Cell Battery Maintenance Instrument |

| Industrial Equipment | High reliability, environmental adaptability | Airtightness Leak Detection Tester |

GuHeng Energy: Your Trusted Expert in New Energy Service Technology Solutions

GuHeng Energy is a high-tech enterprise focused on new energy service technologies, dedicated to providing professional battery testing, maintenance, and solutions for its clients.

1. Company Overview

Founded in Hangzhou, GuHeng Energy has grown into a leading enterprise in the new energy sector through over a decade of technological innovation and industry experience. The company specializes in battery pack testing, balancing maintenance, and airtightness leak detection, developing several industry-first products, such as the Battery Pack Service Terminal Tester (EOS-TEST) and Battery Pack Balancing Maintenance Instrument. These products hold over 30 patents (including 6 invention patents) and 28 software copyrights, have passed multiple CE certifications, and are widely used in new energy vehicles, energy storage systems, and other fields.

2. Technical Strength and Quality Assurance

GuHeng Energy has passed ISO9001 quality management system certification and strictly adheres to standards in product development, production, and sales. All products undergo rigorous quality inspections and aging tests, with reports available from authoritative testing agencies. Additionally, the company offers rapid-response after-sales service and is backed by insurance coverage, ensuring customer peace of mind.

3. Industry Influence

GuHeng Energy actively participates in industry technical seminars and standard-setting initiatives, collaborating with multiple industry associations to advance new energy technologies. The company’s solutions have served numerous well-known enterprises, helping clients improve battery management efficiency and extend battery lifespan.

Choose GuHeng Energy for professional technical support and reliable product assurance. For more information, please contact us.

Frequently Asked Questions

1. How Long Does Battery Capacity Testing Take?

Answer: The duration of battery capacity testing depends on the discharge current and battery capacity. For example, a 100Ah battery discharged at 10A theoretically takes 10 hours. However, in practice, charging time (typically 4-8 hours) and resting time (1-2 hours) must also be considered. Thus, a complete test cycle may take 12-20 hours. To improve efficiency, GuHeng Energy’s automated testing equipment can reduce testing time while enhancing accuracy.

2. How to Determine If Battery Capacity Test Results Are Accurate?

Answer: The accuracy of test results can be evaluated based on the following:

- Equipment Precision: Use calibrated high-precision instruments, such as GuHeng Energy’s Battery Pack Service Terminal Tester.

- Test Conditions: Ensure parameters like temperature and discharge current meet the battery’s specifications.

- Repeatability: Conduct multiple tests and compare results, with deviations within ±2%.

- Data Comparison: Compare test results with the battery’s nominal capacity or historical data to analyze capacity degradation. If results are abnormal, it may be due to uncalibrated equipment, battery aging, or unstable test conditions. Recalibrate the equipment and retest as needed.

3. Does Battery Capacity Testing Affect Battery Lifespan?

Answer: Standard battery capacity testing has minimal impact on battery lifespan, but the following precautions can reduce potential damage:

- Avoid Over-Discharge: Strictly control the cutoff voltage to prevent the battery voltage from dropping below safe levels.

- Control Discharge Rate: High discharge currents can accelerate battery aging; it’s recommended to use 1/10 to 1/5 of the nominal capacity as the discharge current.

- Reduce Test Frequency: Frequent charge-discharge testing may accelerate capacity degradation; schedule tests based on actual needs (e.g., every 6 months). Using GuHeng Energy’s Portable Single-Cell Battery Maintenance Instrumentenables non-destructive testing, maximizing battery protection.