The power battery of new energy vehicles is the core component of modern electric vehicles, and its health condition directly impacts vehicle performance, range, and lifespan. As environmental awareness grows, new energy vehicles are becoming increasingly popular, making effective detection and maintenance of power battery health a focal point in the industry. This article will provide a detailed analysis of the importance of power battery health monitoring, commonly used technologies, and emerging monitoring techniques to help readers better understand this critical field.

Importance of Power Battery Health Monitoring

The power battery holds a pivotal position in new energy vehicles, with its health condition affecting not only vehicle performance but also overall safety and economic efficiency.

Impact of Power Battery Health on New Energy Vehicle Performance

As the energy source for new energy vehicles, the power battery’s health directly determines the vehicle’s range and power performance. When a battery degrades, the vehicle’s driving range significantly decreases, which impacts user experience. Additionally, an unstable battery condition may lead to vehicle malfunctions or safety hazards, making regular health monitoring essential.

Main Causes and Symptoms of Power Battery Degradation

Power battery degradation is primarily caused by the following factors:

- Cycle Aging: As the number of charge-discharge cycles increases, cell capacity gradually declines.

- Temperature Effects: Use in high or low-temperature environments accelerates cell aging.

- Uneven Usage: Variations in individual cell conditions lead to reduced overall performance.

Symptoms include reduced range, lower charge-discharge efficiency, and more.

Commonly Used Power Battery Health Monitoring Technologies

To ensure the normal operation of new energy vehicles, various detection technologies are employed to assess the health of power batteries.

Electrochemical Analysis Methods

This method evaluates battery health by analyzing chemical reactions under different conditions. By measuring parameters such as open-circuit voltage and polarization characteristics, information about internal battery reactions can be obtained to assess lifespan and performance.

Internal Resistance Measurement Technology

Internal resistance is a key indicator of internal battery loss. Measuring internal resistance allows for the evaluation of cell consistency and aging. This method is simple, highly accurate, and widely used.

Capacity Fade Assessment Methods

Capacity fade is a critical indicator of battery aging. By comparing nominal capacity with actual capacity, the degree of battery degradation can be intuitively understood. This method is often used in combination with other techniques to improve accuracy.

Emerging Power Battery Health Monitoring Technologies

With technological advancements, emerging techniques offer new possibilities for power battery health monitoring.

Predictive Models Based on Big Data and Artificial Intelligence

Data Collection and Processing in Health Monitoring

By collecting large amounts of vehicle operation data and utilizing big data analytics, real-time monitoring of power battery conditions can be achieved. This data includes parameters such as temperature, voltage, and current, which can be processed to predict future performance changes.

Role of AI Algorithms in Power Battery Lifespan Prediction

AI algorithms can extract patterns from complex data to predict power battery lifespan. These algorithms are trained on historical data, improving prediction accuracy and providing users with more reliable information.

Trends in Non-Destructive Testing Technologies

Non-destructive testing evaluates battery conditions without disassembling or damaging components. Recent advancements in this field include the use of acoustic waves, infrared imaging, and other methods for internal structure analysis, enabling more efficient and safer testing.

Future Directions for Power Battery Health Management

As the new energy vehicle market grows rapidly, power battery health management technologies continue to advance. Future developments will focus on intelligence, automation, and deep integration with vehicle control systems.

Trends in Intelligence and Automation

Intelligence and automation are two key trends in power battery health management. By incorporating advanced sensor technologies and data analytics algorithms, Battery Management Systems (BMS) can achieve real-time monitoring and automatic adjustments, improving accuracy and reducing the need for human intervention.

- Smart Sensor Applications: Modern BMS widely use smart sensors to monitor critical parameters such as voltage, current, and temperature in real time, providing a foundation for subsequent data analysis.

- Automated Adjustment Functions: Based on sensor data, BMS can automatically adjust charge-discharge strategies to optimize battery performance and extend lifespan, without requiring manual intervention.

- Big Data Analytics: By analyzing vast amounts of data, BMS can identify potential issues and perform preventive maintenance, improving prediction accuracy and reducing failure risks.

Deep Integration of Health Management and Vehicle Control Systems

Deep integration between power battery health management and vehicle control systems is another key direction for future development. Through information sharing and collaborative operations, overall vehicle performance and safety can be significantly enhanced.

- Information Sharing Mechanisms: Efficient information-sharing mechanisms between health management and vehicle control systems allow vehicles to access real-time battery status data and make corresponding adjustments during operation.

- Collaborative Optimization Strategies: Collaborative operation enables the formulation of refined energy management strategies to improve vehicle efficiency. For example, in different driving modes, the vehicle control system can dynamically adjust energy allocation based on battery status.

- Enhanced Safety: Through deep integration, the vehicle control system can quickly respond to anomalies, such as limiting power output or issuing warnings, to ensure driving safety.

Guheng Energy: A Trusted Expert in New Energy Service Technology Solutions

Guheng Energy focuses on the new energy sector, providing professional, efficient, and reliable service solutions for customers.

Dedicated to Technology R&D and Services in the New Energy Sector

Guheng Energy is committed to research and development in new energy technologies, continuously innovating to meet market demands. They offer comprehensive services, including one-stop solutions from design to maintenance.

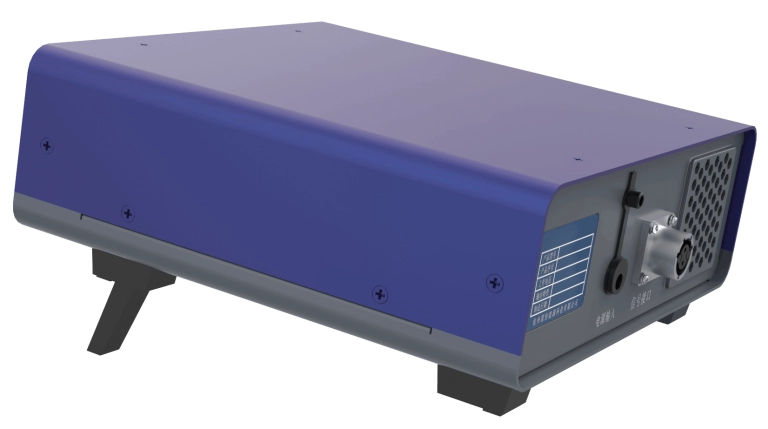

Providing Efficient and Reliable Power Battery Health Monitoring Solutions

The company has developed a range of advanced tools for precise evaluation and monitoring of power battery conditions, ensuring optimal user experience and extended equipment lifespan.

Supporting the Sustainable Development of the New Energy Vehicle Industry

By continuously improving product quality and service levels, Guheng Energy actively contributes to the development of the new energy vehicle industry, supporting green mobility.

In summary, as the new energy vehicle market grows, effective and accurate health monitoring of power batteries becomes increasingly critical. By combining traditional and emerging technologies, a more comprehensive understanding of battery conditions can be achieved, improving vehicle performance and extending lifespan.

Conclusion

In conclusion, the importance of power battery health monitoring in the new energy vehicle industry is undeniable. With technological advancements, various emerging technologies are continuously improving this field. Intelligence, automation, and deep integration with vehicle control systems will propel power battery health management to new heights, providing users with more reliable and efficient service experiences.

Frequently Asked Questions

To help readers better understand power battery health monitoring, we have compiled some common questions and their answers.

How Often Should Power Battery Health Monitoring Be Conducted?

Typically, it is recommended to perform a comprehensive health check on the power battery every 6 to 12 months. However, this frequency depends on factors such as the specific vehicle model, usage environment, and driving habits. If the vehicle is frequently operated in extreme temperatures or high-load conditions, more frequent checks may be necessary. Additionally, in daily use, users should monitor indicators such as range and charge-discharge times to detect potential issues promptly.

Does Health Monitoring Damage the Power Battery?

Proper power battery health monitoring does not damage the battery. Modern testing technologies typically use non-destructive methods, such as internal resistance measurement and voltage monitoring, which assess battery conditions without affecting normal operation. Professional institutions have extensive experience and standardized procedures to ensure the entire testing process is safe and reliable, so users need not worry about negative impacts on the battery.